Over 80% of EV charging happens at home, but installing a garage charger safely starts with your electrical capacity. You’ll confirm service size, run an NEC load calculation, and choose Level 1 or a dedicated 240V Level 2 circuit sized at 125% of continuous load. Permits, GFCI protection, proper grounding, and disconnects aren’t optional. Decide DIY vs pro, avoid code violations, and uncover rebates—because the details can save money and prevent hazards.

Key Takeaways

- Assess your panel: identify service rating, main breaker size, spare spaces, and perform NEC Article 220 load calculations including EV at 125% continuous load.

- Choose charger level to match needs: Level 1 120V for convenience, Level 2 240V 32–48A for faster home charging.

- Size branch circuit correctly: two‑pole breaker and copper conductors at 125% of EVSE nameplate, proper grounding, GFCI or listed EVSE ground‑fault protection.

- Obtain permits and inspections; comply with NEC Article 625 and codes; document load calc, wiring method, and panel details for rebates and inspector review.

- Plan installation details: mounting location, cord reach, disconnect accessibility, voltage‑drop on long runs, smart scheduling, and rebates; hire a licensed electrician for 240‑V work.

Assessing Electrical Capacity and Load Calculations

Before you pick an EV charger, confirm your home can support it by performing a code-compliant load calculation. Start by identifying service rating, main breaker size, and available spaces. Tally fixed appliances, HVAC, small-appliance and laundry circuits, then apply NEC Article 220 demand factors. Treat EV charging as a continuous load at 125% of nameplate current. Conduct Load Profiling to understand typical usage and Peak Estimation to model worst-case simultaneous demand.

Verify panel bus and feeder ampacity can carry the calculated load, and check voltage drop if the run is long. Size the branch circuit, overcurrent device, and conductors accordingly, considering ambient temperature and conduit fill. If capacity is insufficient, plan a panel or service upgrade and coordinate with your utility and AHJ early.

Level 1 Vs Level 2 Chargers: Choosing the Right Option

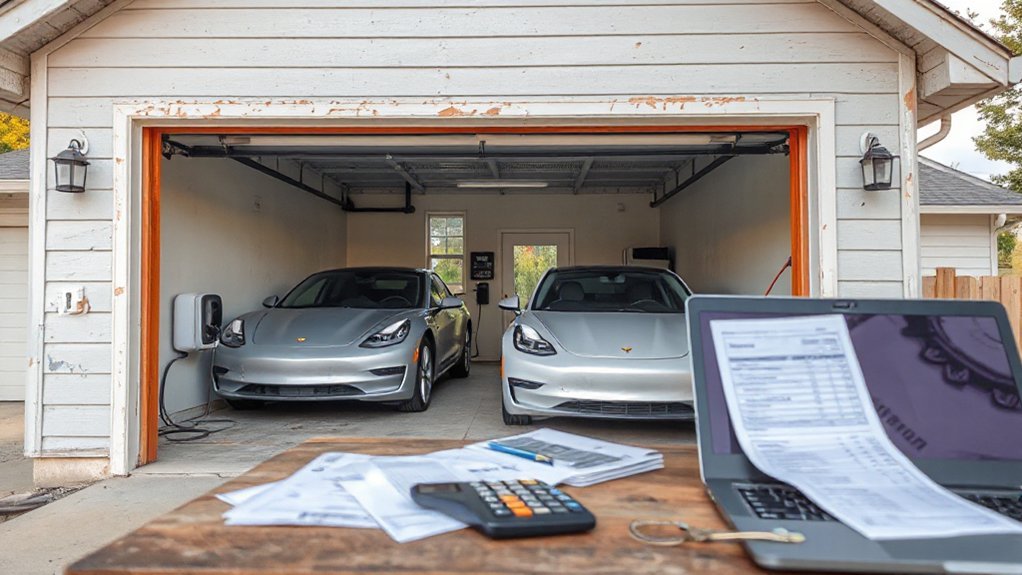

With your load calculation in hand, select between Level 1 (120V) and Level 2 (240V) based on charging speed needs, panel capacity, and code constraints. Level 1 adds roughly 3–5 miles per hour, suits overnight topping, and plugs into a dedicated 15–20A circuit. Level 2 delivers about 20–40 mph, reduces Range Anxiety, and typically requires a 40–60A two-pole breaker with GFCI protection. Match the choice to Lifestyle Fit, commute length, and dwell time. Keep cords tidy and receptacles listed for EVSE.

| Option | Typical Output | Best For |

|---|---|---|

| Level 1 | 1–1.9 kW | Small daily miles, apartments |

| Level 2 (32A) | ~7.7 kW | Most homes, faster turnaround |

| Level 2 (48A) | ~11.5 kW | Long commutes, multi-EV homes |

Verify proper conductor sizing, temperature ratings, and EVSE listing; avoid extension cords.

Permits, Codes, and Inspection Requirements

Even when the work seems straightforward, most jurisdictions require a permit for an EV charger circuit, and the Authority Having Jurisdiction will expect compliance with the NEC (Article 625 and local amendments). Submit a load calculation, panel rating, proposed breaker size, and wiring method. Use a dedicated branch circuit sized at 125% of the EVSE’s continuous load, with listed equipment, proper grounding and bonding, GFCI where required, and clear labeling. Maintain working clearances and mounting heights, protect cables, and use approved conduit or raceways.

Plan for inspections: rough-in (conductors, boxes, grounding) and final (connections, functionality). Confirm utility requirements for service upgrades. Check Zoning Restrictions and Historic Preservation rules for exterior runs or visible equipment. In multifamily settings, address firestopping and load-management approvals by inspectors.

DIY Vs Professional Installation: What’s Recommended

While a capable DIYer can mount the EVSE and tidy conduit runs, installing or modifying a 240‑V branch circuit for charging is often licensed electrical work and should be done by a qualified electrician. You’re responsible for safe clearances, GFCI protection, and proper load calculations; a pro verifies panel capacity, bonding, and overcurrent protection to the latest code. Professional installation also preserves Warranty Differences and aligns with manufacturer commissioning requirements. If something goes wrong, your contractor’s Liability Insurance protects you; your homeowner’s policy may not.

- Verify the charger’s location: reach of the cord, ventilation, and drip loops away from water.

- Label the disconnect and breaker; keep the charger on a dedicated circuit.

- Keep records: permit, inspection sign‑off, photos, and serial numbers for future reference.

Costs, Timelines, and Typical Project Steps

Expect a clear scope and budget once you decide who installs the charger. You’ll start with a site walk, estimate, and written proposal detailing labor, permits, Material sourcing, hardware, and inspection fees. For a standard wall-mounted Level 2 unit, expect $300–$1,500 in installation labor, plus permits and materials, excluding any service upgrades. Timelines typically run 1–3 weeks: proposal and permitting (3–10 days), procurement (2–5 days), installation day (3–6 hours), and final inspection (1–7 days). Verify the contractor’s license, insurance, and adherence to applicable codes. Require labeled photos, test results, and a warranty in the closeout packet. Practice Contingency planning: budget 10–15% for surprises, confirm lead times, and schedule inspection early. Don’t energize the charger until it passes inspection. Document labels, clearances, and emergency shutoff.

Panel Upgrades, Circuits, and Wiring/Outlet Requirements

First, you verify service panel capacity with an NEC Article 220 load calculation; if the existing service can’t support the EVSE, plan a panel or service upgrade. Size the dedicated EV circuit as a continuous load per NEC 625 (125% of the EVSE nameplate), and select a matching breaker. Choose conductors and a wiring method that meet code and voltage-drop limits—e.g., copper THHN/THWN-2 in conduit or NM-B where permitted—use GFCI for receptacle-fed units, and pull permits for inspection.

Service Panel Capacity

Before you choose a charger, verify your service panel can support the continuous EVSE load. Use a NEC load calculation to compare existing demand with the main’s ampacity. EVSE is a continuous load, so plan for 125% of its rating. Confirm sufficient breaker spaces and busbar rating. If the calculation exceeds capacity, schedule a service upgrade (e.g., 100A to 200A) or a load management solution approved by your AHJ. Consider ventilation considerations for enclosures and clearances around the panel.

- Verify main breaker rating, bus rating, and available spaces match the load calc.

- Label the EV circuit and disconnect per NEC 110.22; adopt consistent labeling practices.

- Maintain working clearances (NEC 110.26); keep the panel accessible and dry.

Use a licensed electrician for compliant, safe upgrades.

Circuit Sizing and Wiring

Once the load calculation confirms capacity, size the EV branch circuit and wiring to the EVSE’s nameplate and NEC 625. Treat EVSE as a continuous load; multiply the nameplate current by 125% to pick the breaker and conductor ampacity. Use a dedicated 2‑pole breaker, copper conductors when possible, and 75°C ampacity ratings that match equipment terminations. For long runs, limit voltage drop to ~3%. Hardwired units need equipment grounding conductor; neutrals are unnecessary unless required by the EVSE. Receptacle installs in garages require GFCI protection and a NEMA configuration per the listing (often 14‑50). Follow conductor Color coding, proper bonding, and labeling at the panel. Verify Terminal torque with a calibrated tool, and land conductors only once per lug. Per manufacturer and code requirements.

Safety, GFCI, and Smart Features for Daily Charging

You must meet NEC/CEC requirements for EVSE branch-circuit sizing, overcurrent protection, and labeling before you energize the system. Provide ground-fault protection using a GFCI breaker or EVSE‑integrated GFCI as required by code, and avoid stacking GFCIs that cause nuisance trips. Then enable smart scheduling and load management so you charge off‑peak, share capacity across circuits, and don’t exceed service limits.

Electrical Code Compliance

While convenience matters, electrical code compliance governs how you install and use a garage EV charger. You’ll pull permits, schedule inspections, and follow the NEC as modified by Local Amendments. Verify your home’s service capacity and complete a load calculation before adding a dedicated branch circuit. Size conductors and overcurrent protection to the EVSE’s nameplate and Product Listings, not marketing specs. Maintain working clearances, proper mounting height, and approved wiring methods. Use listed enclosures, fittings, and wet-location ratings where exposure exists. Label disconnects, directories, and load management devices. Configure smart charging features to stay within circuit limits and utility programs.

- Choose listed EVSE and components recognized for the application.

- Provide a readily accessible disconnect when required.

- Document permits, calculations, and approvals for your records.

Ground Fault Protection

How do you keep a routine charge from becoming a shock or fire hazard? You install ground-fault protection and verify it works. NEC 210.8 requires GFCI for garage receptacles, and NEC 625 requires listed EVSE with integrated ground-fault protection. Use a Class A GFCI receptacle or breaker for plug‑in units, and a listed wallbox with built‑in CCID/DC leakage detection for hardwired systems.

GFCI’s Historical Origins trace to 1960s life‑safety research; today’s Research Advances deliver self‑testing, auto‑reclosing only when safe, and DC fault sensing that trips before arcing escalates. Mount equipment on a grounded metallic system, keep bonding intact, and avoid shared neutrals. Test the GFCI and EVSE monthly, inspect cords for damage, and replace any device that trips repeatedly or won’t reset. Seek service.

Smart Scheduling, Load Management

Often, smart scheduling and load management turn daily charging into a safer, cheaper, code‑compliant routine. You set the EVSE to charge off‑peak, align current limits with your panel capacity, and let the system coordinate with GFCI protection. Use Predictive Scheduling to pre‑heat or pre‑cool while rates are low, then taper to protect breakers and conductors. If you share circuits, enable load sharing so simultaneous loads never exceed the feeder rating.

- Define maximum amperage per NEC 625 nameplate and breaker sizing.

- Apply Behavioral Incentives: notify you when delaying saves money and reduces peak demand.

- Log faults, test GFCI monthly, and update firmware for safety patches.

Verify utility rate signals, and integrate with demand‑response programs. Document settings on the panel directory for inspectors and future audits.

Rebates, Tax Incentives, and Considerations for Renters, HOAs, Detached or Older Garages

Before you buy a charger, map the incentives and constraints that will shape your installation. Check federal, state, and utility programs, confirm incentive eligibility, and note documentation, permit, and inspection requirements. Many rebates demand a licensed electrician, UL-listed equipment, and load calculations per NEC Article 220.

If you rent, secure landlord permissions in writing, including scope, ownership, and restoration. For HOAs, submit plans, site photos, and stamped drawings; reasonable accommodation laws may apply, but you must follow architectural rules.

For detached or older garages, budget for trenching and dedicated circuits. Use buried PVC or EMT with correct burial depth, GFCI protection, and an outdoor-rated disconnect. Evaluate service capacity, bonding, and grounding; upgrade panels with AFCI/GFCI where required. Keep receipts for tax credits filings.

Conclusion

You can install a garage EV charger confidently when you calculate loads, confirm capacity, and choose the right Level 2 EVSE. Pull permits, follow the NEC, and provision a dedicated 240V circuit sized at 125% of continuous load. Prioritize proper grounding, GFCI, and a disconnect. Prefer a pro for panel work, wiring, and inspection readiness. Schedule smart charging, seek subsidies, and satisfy HOA or landlord rules. Plan, permit, and protect—safety first, savings second, charging third.