From USB‑C PD and Qi on your desk to CCS, NACS, CHAdeMO, and GB/T at the curb, you navigate a maze of connectors and protocols. You weigh ISO 15118, OCPP, and Plug‑and‑Charge against certification, safety envelopes, and thermal limits. You factor SiC/GaN power stages, liquid‑cooled leads, and PKI into interoperability and lifecycle risk. To make compliant, future‑proof choices, you need to see how these specs align—and where they clash…

Key Takeaways

- Major EV standards: CCS, NACS, CHAdeMO, GB/T; differing connectors, protocols (PLC, CAN), and power up to ~1000 V, 400–615 A.

- Negotiation manages safety and power: pilot/proximity, HVIL, ISO 15118/DIN 70121 messages, live temperature feedback, derating by cable, connector, and battery limits.

- Consumer charging uses USB-C Power Delivery and Qi/Qi2; PD negotiates up to 240 W (EPR), while Qi enforces FOD and thermal limits.

- Safety and compliance rely on IEC/SAE/UL standards, residual current monitoring, ground sequencing, contactor interlocks, insulation monitoring, and certified interoperability testing.

- Power electronics use SiC/GaN, active PFC, isolated DC/DC, liquid cooling, achieving >98% efficiency, grid EMC compliance, and reliable high-current DC fast charging.

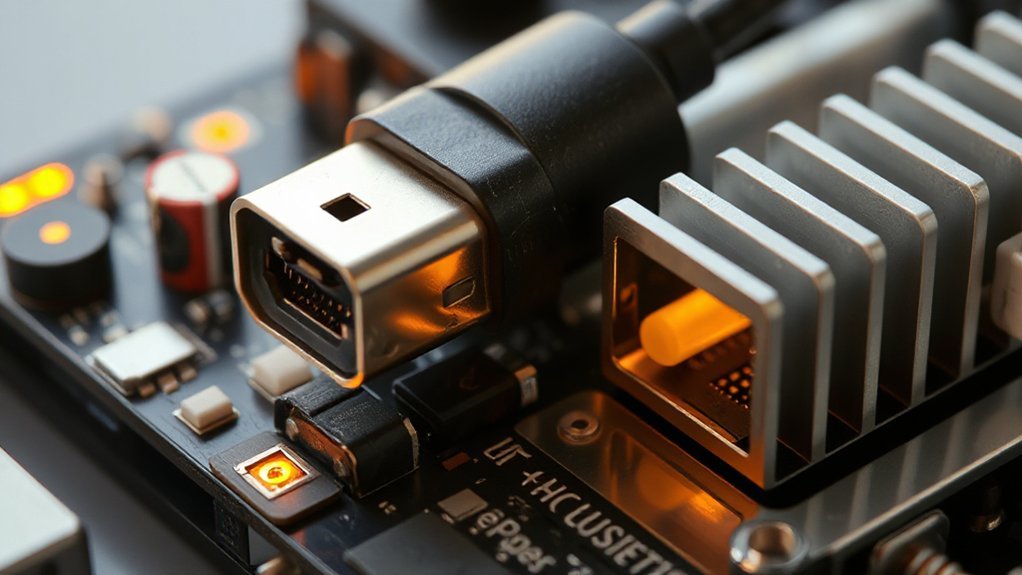

Consumer Charging: USB-C Power Delivery and Qi Wireless

While both aim to deliver power safely and efficiently, USB-C Power Delivery (USB PD) and Qi define distinct, interoperable protocols, signaling methods, and power profiles. With USB PD, you negotiate via the CC channel using PDOs, PPS, and role swaps to source or sink up to 240 W under EPR, with explicit OCP/OCP and cable-ID constraints. You manage Thermal Throttling via USB PD’s battery/temperature status and stepwise voltage/current adjustments. With Qi, you implement inductive coupling, in-band ASK/FSK control, and certified power classes—from Baseline to EPP and Qi2’s Magnetic Power Profile—while enforcing FOD and thermal limits. You validate interoperability across the Accessory Ecosystem through certification (USB-IF, WPC), guarantee safe detach/attach states, and coordinate charge management between wired and wireless paths to prevent contention and overlap.

EV Connectors and Protocols: CCS, NACS, CHAdeMO, and GB/T

You’ll compare CCS, NACS, CHAdeMO, and GB/T by pin layout, signaling, and mechanical keying, as each defines mating, safety, and lock behavior. You’ll quantify rated voltage, current, and supported charging modes to map achievable power and session speed across AC and DC. You’ll assess interoperability through protocol negotiation, network authentication, and adapter limitations to determine when cross-standard charging is feasible.

Connector Physical Differences

Connectors are physical interfaces whose geometry, pin layout, and materials determine interoperability and power delivery limits. You assess CCS as two DC pins integrated with Type 1/2 AC, oval shroud, latch, CP/PP pins; NACS uses compact layout with shared housing, internal latch; CHAdeMO employs separate round DC connector with screw/lock and dedicated signal pins; GB/T specifies mirrored Type 2 form factor with separate DC connector and keying. Compare insertion geometry, keying, and strain relief; misalignment prevention via chamfers and polarizing ribs. Contact metallurgy (silver-plated copper alloys) and plating thickness define resistance and wear. Sealing profiles and IP ratings govern performance. HVIL, ground-first/last sequencing, and proximity detection reduce arcing and enforce safe mating. Handle ergonomics, cable bend radius, and receptacle reinforcement influence reliability in duty.

Charging Speeds and Power

Because charging power is bounded by voltage, current, and thermal limits, the major EV interfaces define explicit envelopes in their base standards and control protocols. You size expectations using their rated voltage and current: CCS up to 1000 V and 500 A; NACS up to 1000 V and 615 A; CHAdeMO typically 500 V and 125–400 A (CHAdeMO 2.0/3.0 higher); GB/T DC up to 1000 V and 600 A. Each stack negotiates limits via state-machine messages and live temperature feedback, then derates by cable, connector, and cell conditions. Apply Benchmarking standards to compare effective session power across SOC bands, not just peak. Map station nameplate to vehicle acceptance curves to anticipate taper. Align charger power, pack C‑rate, and cooling to minimize Wait time perception.

Interoperability and Adapters

Although EV ecosystems segment by connector and protocol, interoperability hinges on aligning mechanical, electrical, and communications layers defined by CCS (IEC 62196-3; ISO 15118/DIN 70121), NACS (SAE J3400), CHAdeMO (CHAdeMO 1.x/2.0), and GB/T (GB/T 20234; GB/T 27930). You evaluate plug geometry, pin assignments, voltage/current envelopes, and signaling: PLC over powerlines for CCS/NACS, CAN for CHAdeMO, and GB/T message sets. Adapters must translate pilot states, proximity, and handshake timing, while preserving safety interlocks and fault codes. Prioritize ISO 15118 Plug&Charge mapping, DIN 70121 fallbacks, and legacy compatibility for earlier vehicles. For DC, require contactor coordination and insulation monitoring equivalence. For AC, verify PP/CP resistor semantics stay intact. Build an accessory ecosystem with certified adapters, firmware updaters, and conformance tests to reduce cross-standard friction and errors.

Interoperability and Certification Across Devices and Vehicles

You align cross-platform protocols by mapping message sets and semantics across CCS/NACS/CHAdeMO and ISO 15118/OCPP to guarantee feature parity and backward compatibility. You validate conformance in accredited labs using test suites for ISO 15118, IEC 61851, SAE J1772, and OCPP, and obtain certification marks via plugfests and programs (e.g., CharIN, UL, OpenADR). You implement roaming and authentication through OCPI/eMIP and hub operators, enforcing trust with PKI, Plug&Charge (ISO 15118-2/-20), and token standards like RFID/ISO 14443 for settlement.

Cross-Platform Protocol Alignment

While ecosystems evolve, cross-platform protocol alignment guarantees EVs, EVSE, and backends interoperate under precise specifications and verifiable certification. You implement harmonized message schemas, transport bindings, and security profiles so OCPP, ISO 15118, OCPI, and OEM APIs negotiate capabilities consistently. Prioritize API Standardization to normalize endpoints, authentication, versioning, idempotency, and error taxonomies across providers. Apply Semantic Mapping to reconcile identifiers for tariffs, locations, charging profiles, metering, tokens, and firmware so data graphs remain unambiguous. Define state machines that align connection, authorization, charging, and settlement phases, including timeout budgets and retry logic. Converge event models around telemetry granularity, time bases, and delivery guarantees. Validate cross-protocol feature parity through canonical test vectors and conformance matrices. You then reduce integration friction and prevent vendor lock-in across deployments globally.

Certification Frameworks and Labs

From protocol alignment comes enforceable interoperability through accredited certification and labs. You operationalize specs by submitting hardware and firmware to conformance, interoperability, and safety programs mapped to IEC, ISO, SAE, and UL requirements. You execute standardized test suites against reference implementations, golden EVs/SECCs, and calibrated fixtures to validate signaling, timing, error handling, and fallback behavior. Robust accreditation processes guarantee labs maintain traceability, proficiency testing, and impartiality. You verify CC, CHAdeMO, and ISO 15118 physical, link, and application layers under defined environmental and EMC profiles. You document deviations, close nonconformities, and re-run regressions across software builds. Scalable laboratory infrastructure—HIL benches, load banks, cyclers, and protocol analyzers—lets you qualify variants, ensuring chargers and vehicles interoperate predictably across releases and markets. Maintain records, certificates, and change control.

Roaming and Authentication

As roaming scales across networks and markets, authentication must adhere to open protocols and cryptographic profiles. You implement OCPI for inter-network settlement and authorization, OCPP for CSMS control, and ISO 15118-2/-20 for Plug&Charge with V2G-PKI. You anchor Federated Identity to Trust Frameworks that define certificate policies, revocation, and audit. Use eRoaming hubs or direct peering while enforcing OAuth 2.0/OpenID Connect for app-based access and token exchange. Validate contract certificates, perform mutual TLS, and staple OCSP to meet latency targets. Align with IEC 63119, DIN SPEC 70121, and ETSI eIDAS profiles where applicable. Test cross-vendor flows: token provisioning, roaming authorization, session start/stop, CDR delivery, and dispute resolution. Certify against conformance suites and mandate continuous certificate lifecycle management. Monitor trust anchors and rotate keys on compromise.

Safety by Design: Protections, Standards, and Thermal Limits

Because safety is non-negotiable, charging interfaces embed protections mandated by core standards and enforced through protocol handshakes. You implement IEC 61851/ISO 15118 or CHAdeMO/GB/T states to verify earth continuity, proximity detection, and control pilot duty cycle before energizing. Material Selection follows UL 94, IEC 62196 creepage/clearance, and IP rating thresholds. You apply Failsafe Design with interlock loops, residual current monitoring per IEC 62752/62955, and contactor weld detection. Overcurrent, overvoltage, and isolation limits map to IEC 61010 and UL 2231 leakage boundaries. You negotiate current caps and temperature derating via digital messages, halting on CRC faults or out-of-range thermistors. Connector pin sensors enforce thermal trip points; duty cycle reduces first, then opens. Event logs and signed error codes support post-incident traceability across fleet and field.

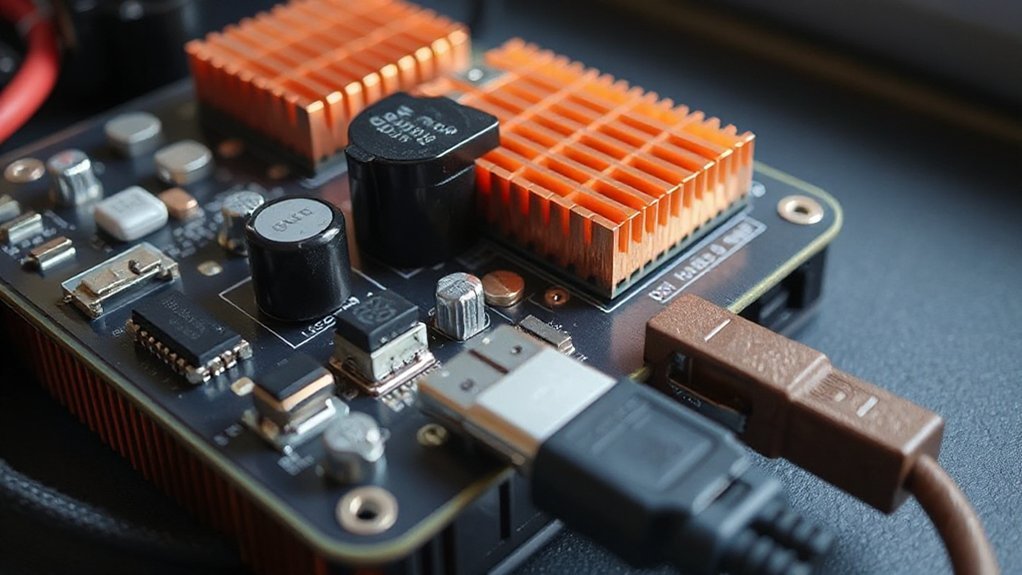

Power Electronics Behind Fast Charging: GaN, SiC, and Thermal Management

While fast-charge current and bus voltage climb, the power stage must satisfy DC EVSE requirements in IEC 61851-23/-24 and grid/EMC limits such as IEEE 519 THD, IEC 61000-3-12 harmonic current, CISPR 11 Class A emissions, and IEC 61000-4 surge/ESD immunity. You architect active front-end PFC and isolated DC/DC stages using SiC for high-voltage switching and GaN for high-frequency isolation, then prove GaN reliability and AEC-Q101 device robustness with JEDEC JESD47 stress results. Specify SiC packaging—low-inductance modules, DBC/AMB substrates, sintered attach—to control dv/dt, overshoot, and EMI. Validate efficiency >98%, PF ≥0.99, and current ripple per IEC 61851 profiles. Engineer thermal paths via liquid cold plates, graphite TIMs, and sensorized heat-spreaders, meeting UL 2202 temperature rise and IEC 60721 derating across ambient, altitude, and duty cycle.

DC Fast Charging and Megawatt Systems for Heavy Transport

Driven by turnaround demands in trucking, buses, and off‑highway fleets, DC fast charging scales from CCS high‑power charging into Megawatt Charging Systems that deliver 0.5–3 MW with specification-led interoperability.

You size cables, liquid cooling, and voltage classes (800–1,250 V DC) to meet duty cycles and thermal limits. Compliance anchors on IEC 61851-23/-24, IEC 62196-3, SAE J3068 for three-phase AC interfaces to depots, and emerging MCS specs defining 3 kA pins, safety interlocks, and EMC.

| Parameter | CCS HPC | MCS |

|---|---|---|

| Max power (kW) | 350 | 500–3000 |

| Voltage (V) | 500–1000 | 800–1250 |

| Current (A) | ≤500 | ≤3000 |

You plan site topology around load management, fault clearing, and clearances, while aligning Infrastructure financing with Route electrification milestones, grid interconnection studies, and uptime SLAs. Specify modularity and upgrade paths.

Smart Features and Automation: ISO 15118, Plug-and-Charge, and Payment

High‑power hardware only delivers fleet value when the communications stack automates authentication, billing, and control via ISO 15118. You implement Plug-and-Charge with ISO 15118-2/20, binding TLS, certificates, and contract IDs so vehicles authenticate without RFID. You enforce OCPP 2.0.1 for charger-backend control and align payment using OCPI for roaming. With Wallet Integration, you map contracts to driver, asset, and cost center. You configure Subscription Models through tariff tables and pricing elements, not ad hoc fees. Certificate lifecycle, PKI trust chains, and revocation lists remain non-negotiable. Log events with standardized error codes for field diagnostics.

- Provision vehicle certificates via OEM or fleet PKI; rotate on schedule.

- Validate tariff selection with signed metering values and session IDs.

- Push firmware and contract data using secure WebSocket channels.

Bidirectional Energy and Grid Integration: V2X, Wireless, and Managed Charging

Orchestrating bidirectional energy flows starts by implementing ISO 15118‑20 Bidirectional Power Transfer (AC/DC, incl. V2G, V2H, and V2B). You use its schedules, meter info, and power/energy setpoints to modulate export/import, harmonized with IEC 61851 and IEC 61850 profiles for DER coordination. For wireless V2X, align EVSE with IEC 61980 and SAE J2954, and map control to ISO 15118‑20 messages.

Managed charging relies on OCPP 2.0.1 Smart Charging, IEC 63110, and utility signals via OpenADR 2.0b or IEEE 2030.5 to dispatch fleets for Frequency regulation and peak shaving. In Community microgrids, you implement IEEE 1547 interconnection, use 15118‑20 energy transfer modes, and apply aggregated constraints, ensuring feeder limits and state-of-charge bounds while honoring market-optimal setpoints and user preferences, and mobility, availability, and charging policy targets.

Security, Sustainability, and Lifecycle Impacts of Charging Ecosystems

While enabling reliable power exchange, charging ecosystems must anchor security, sustainability, and lifecycle performance in codified standards. You implement authenticated boot, certificate-based identities, and encrypted OCPP/OCHP to satisfy ISO 15118-20 and IEC 63110. You enforce firmware updates, tamper logging, and supply-chain attestations. For sustainability, you align metering, disclosures, and energy sourcing with ISO 14064 and PAS 2060. You treat Lifecycle Assessment as a requirements input, not a report, linking charger design, service intervals, and decommissioning to KPIs and Battery Recycling pathways under IEC 62660/UL 1974.

- Map data retention, privacy, and incident reporting to ISO 27001, NIST IR 7628, and GDPR.

- Specify modular power stages and repairability per IEC 62980 to extend MTBF.

- Track embodied carbon, reuse rates, and take-back logistics via digital product passports.

Conclusion

You anchor your design to specifications: USB‑C PD 3.1 delivers 240 W, Qi 2.0 standardizes magnetic alignment, CCS and NACS define pins and signaling, and ISO 15118‑20 automates contracts, V2G, and security. You verify with OCPP and PKI, certify conformance, and manage thermals with SiC, GaN, and liquid‑cooled cables. Build to limits, test against profiles, and ship updates. Here’s a stat: PD 3.1’s 240 W is a 140% increase over the original 100 W cap.