You might not know Zappi’s built‑in PEN‑fault protection can legally replace an earth rod—only when commissioned to BS 7671 and IEC 61851 with the correct RCD Type A + 6 mA DC. You’ll need the right phase size, CT placement for solar/load balancing, and documented grid permissions. Get the steps, costs, and pitfalls that decide whether your install is compliant, future‑proof, and cheaper—or not.

Key Takeaways

- Supports Type 2 Mode-3 AC charging to IEC 61851/62196; 7.4 kW single‑phase typical, 11/22 kW three‑phase if supply and EV support.

- Built-in Type A RCD with 6 mA DC detection and automatic PEN-fault protection; install to BS 7671 Section 722 and manufacturer instructions.

- CT clamps enable solar/battery integration and dynamic load balancing, diverting surplus export to the EV with Eco, Eco+ or Fast modes.

- Typical install takes 3–6 hours: dedicated circuit, correct CT placement, firmware update, commissioning tests, and DNO notification where required.

- Hardware typically £700–£1,000; choose tethered or socketed Type 2, confirm warranties, firmware updates, OCPP/Wi‑Fi connectivity, and session logging.

What the Zappi Charger Is and How It Works

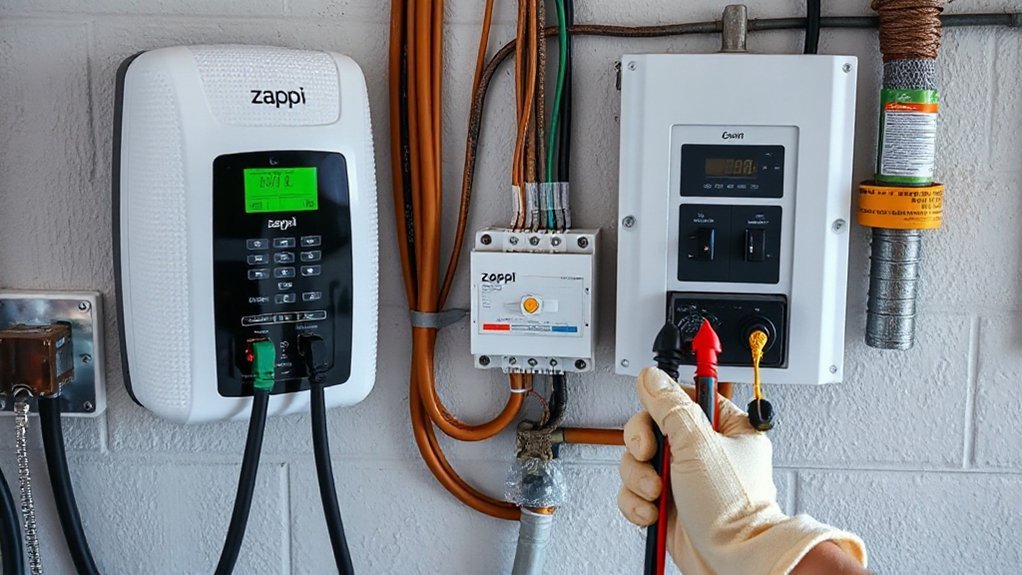

The Zappi is a smart, mode-3 EV charge point that integrates with your home’s electrical system and on-site generation to deliver safe, standards-compliant charging. Here’s a concise product overview: you get Mode 3 AC charging per IEC 61851 with adjustable current, built‑in RCD Type A + DC leakage detection, and automatic PEN fault protection. It verifies supply integrity, earth continuity, and temperature before energizing. For operational mechanics, Zappi uses a PWM control pilot to negotiate current with the vehicle, measures line currents via CTs, and dynamically balances load to protect your main fuse. It derates on thermal events, logs sessions, supports schedules, and RFID authorization. Installation supports single- or three-phase wiring, correct cable sizing, and BS 7671-compliant isolation and bonding by a qualified electrician.

Solar, Battery and Microgeneration Integration

When paired with on-site PV, battery storage, or wind/CHP, Zappi uses correctly installed current transformers (CTs) to track real-time grid import/export and diverts only surplus generation to the EV within IEC 61851 current limits. You choose Eco, Eco+ or Fast to align current with export and prevent import. Configure CT orientation and grid limits to meet DNO and G99/G100 constraints. With a house battery, you prioritize SOC, then spill excess to the car, maintaining breaker diversity. In community microgrids, Zappi respects site import caps to protect feeders and energy sovereignty.

Divert surplus renewables to your EV, honoring grid limits, batteries, and community import caps.

- Calibrate CTs, set min/max currents, enable load balancing to protect the main fuse rating.

- Use surplus-only mode; add export thresholds and phase-imbalance limits.

- Verify RCD Type A, PEN protection, and document settings for audits.

Choosing the Right Model, Phase, and Cable Option

Before you choose a Zappi model, verify supply type (single- or three-phase), main fuse rating, and applicable standards (IEC 61851/62196, BS 7671 Section 722), then size the EVSE to stay within permitted demand. Select 7.4 kW single-phase for UK services; choose 11 or 22 kW three-phase only where the service and EV onboard charger support it. Use dynamic load management to respect main fuse limits and prevent nuisance trips. Decide between tethered (faster, convenient) and socketed (flexible) options; specify Type 2 to IEC 62196-2. Confirm PEN-fault protection, DC leakage monitoring, and RCD Type A compliance. Check ingress and impact ratings suitable for location. Consider cable length, lock features, and aesthetic finishes. Compare firmware and warranties, then factor tariffs and retailer promotions when evaluating cost.

Site Survey, Permissions, and Grant Eligibility

After selecting compliant hardware, conduct a formal site survey to verify installation feasibility, permissions, and funding routes. You’ll document mounting location, cable routing, meter proximity, and service intake; capture photos, dimensions, and obstructions. Confirm property ownership, boundaries, and any planning constraints (conservation areas, listed status). If you’re a tenant, secure Landlord Consent in writing. Check off-street parking suitability and grid connection notification obligations. Review grant schemes and your eligibility criteria, aligning evidence to each Application Timeline to avoid lapses.

- Map stakeholders: DNO, landlord/freeholder, building manager, insurer; assign actions and response dates.

- Compile paperwork: proof of residence, vehicle eligibility, EPC rating, site photos, risk assessment.

- Build a schedule: survey completion, consent receipt, grant submission, DNO notification, installation booking, contingency and buffer days

Electrical Requirements and Safety Features

Although compact, the Zappi must sit on a dedicated circuit designed and verified to BS 7671:2018+A2:2022 and the IET Code of Practice for EV charging. Specify supply capacity, conductor sizing, and a lockable local isolator. Fit a suitably rated MCB or RCBO, considering RCD types: Zappi provides 6 mA DC protection, so pair it with a Type A device unless your design demands Type B. Provide Surge protection to BS 7671 Section 443, coordinated at the origin and the EV circuit. Verify earthing: Zappi includes open-PEN protection for PME systems, so you won’t need an earth rod in typical domestic installs. Confirm ADS, touch-voltage limits, and Zs comply. Maintain IP-rated glands, correct cable routes, and mechanical protection. Test, certificate, and label for user safety.

CT Clamps, Grid-Limit Settings, and Load Balancing

You’ll position CT clamps on the main incoming conductors with correct orientation and secure routing, following manufacturer guidance and local electrical codes. You’ll configure the grid limit to match your service capacity and main breaker rating to prevent overload and nuisance trips. You’ll enable dynamic load balancing so the charger modulates current in real time, protecting supply infrastructure and maintaining compliance.

CT Clamp Placement

Because accurate current measurement underpins safe operation, place Zappi CT clamps correctly on the supply tails to monitor grid import/export and enable load balancing. Fit one clamp per phase on the incoming tails between meter and consumer unit, with the core fully closed and centered. Observe arrow orientation; verify polarity in the Zappi readings, correcting if import shows negative. Keep CT leads away from mains conductors, use twisted pair where possible, and terminate in the CT input or Harvi. Isolate the supply, follow BS 7671 and local codes, and label the CTs. Minimize visual impact with tidy routing and covers; respect homeowner opinion on aesthetics.

1) Location: before the main switch, after meter.

2) Orientation: consistent across phases.

3) Commissioning: check values under load.

Grid Limit Configuration

While the CT clamps deliver real-time import/export data, you must configure Zappi’s Grid Limit so charging never exceeds the service capacity and remains compliant with BS 7671 and IEC 61851. Confirm the supply rating and main fuse size, then set the grid current limit per phase in the installer menu. Assign each CT to grid, generation, or battery, and verify polarity. Enable limit enforcement so Zappi ramps or suspends charge when aggregate demand approaches the threshold. Document settings for utility coordination and notify your DNO where required. Perform validation: induce household load, observe measured current, and confirm the charger backs off before the fuse rating. Mitigate cybersecurity implications by setting an installer PIN, disabling unused interfaces, and updating firmware to the latest signed release.

Dynamic Load Balancing

With the grid limit set and CTs assigned, implement dynamic load balancing to keep aggregate current within BS 7671 and IEC 61851 constraints as site load varies. Verify CT clamp polarity and phase mapping so the charger reads import/export correctly; enable per-phase monitoring. Set min/max current, ramp rates, and shedding thresholds to protect fuses and prevent overheating. For multi‑unit sites, enable fleet coordination so sessions share capacity, using predictive algorithms to forecast load and PV swings. Configure loss‑of‑CT and overcurrent failsafes to drop to safe current or pause.

- CT setup: Fit on meter tails, arrow to load; verify rotation.

- Grid-limit: Reserve headroom for surges; apply diversity; enforce current granularity.

- Control: Tune ramp rates and debounce; prioritize critical circuits; log events regularly.

Step-By-Step Installation Overview

Seven core stages take you from pre‑site assessment to final commissioning of your Zappi EV charger, executed to NEC/BS 7671 and the manufacturer’s instructions.

Stage 1—pre‑site assessment: verify service capacity, earthing type, prospective fault current, cable routes, and permitting.

Stage 2—Unboxing checklist: confirm model, tethered lead, fixings, CT clamps, PEN/RCD modules, seals; inspect for damage.

Stage 3—Isolate supply, mount the backplate to suitable substrate, maintain clearances, and preserve IP rating.

Stage 4—Pull a dedicated circuit, install breaker, Type A RCD or integral protection, and surge protection if required.

Stage 5—Fit CTs on mains/solar per polarity and orientation; route low-voltage cabling separately, mechanically protected.

Stage 6—Terminate conductors, torque to spec, bond, label, and test insulation, polarity, R1+R2, and Zs.

Stage 7—Energize, verify; Time estimates: 3–6h.

App Setup, ECO Modes, and Smart Scheduling

How do you commission the smart side safely and correctly? Power the Zappi, update firmware to latest via the app, and pair your hub over WPA2-secure Wi‑Fi. Verify CT clamps are assigned correctly (grid, solar, battery) and that phase settings match your supply. Enable two-factor login, review privacy settings, and restrict PIN control. Calibrate ECO, ECO+ and Fast: set minimum charge current, export thresholds, and vehicle awake timers to avoid nuisance ramping. Validate residual current protection tests and confirm load balancing limits.

- App setup: create a dedicated account, apply calendar integration only after granting least-privilege access, then lock installer menu.

- ECO modes: prioritize surplus PV, set import cap, and configure stop/start hysteresis.

- Smart scheduling: define compliant schedules, enforce charging windows, and add grid-safety overrides.

Typical Costs, Tariffs, and Ongoing Running Expenses

Most owners should budget for three cost buckets: hardware, installation to BS 7671/IEC 60364-7-722, and ongoing energy plus standing charges. Expect the Zappi unit, tethered or untethered, to run £700–£1,000. Installation typically adds £400–£900, covering DNO notification, circuit design, Type A RCD with 6 mA DC protection, PEN-fault protection, CT clamps, and certification. A load assessment and safe cable routing reduce thermal and shock risk. Energy costs depend on tariff: off-peak time-of-use or dynamic pricing can cut p/kWh, but standing charges persist. Monitor seasonal variation in rates and your home’s baseload. Use the Zappi app and a smart meter for billing transparency and export credits. Budget for periodic inspection and RCD testing, firmware updates, and occasional cable/plug replacement. Keep earthing arrangements inspected by professionals.

Compatibility, Warranties, and Common Pitfalls

While Zappi supports Type 2 AC charging on single- and three‑phase supplies and can coordinate with PV/battery via CT clamps, you must confirm electrical compatibility, earthing type (e.g., PME with PEN-fault protection), load capacity, and reliable comms before purchase. Verify OCPP, Wi‑Fi/Ethernet reliability, and CT routing distances. Confirm RCD Type A/6 mA DC detection, bonding, surge protection, and enclosure IP rating on site. Check your DNO approvals for service upgrades or export limits. For warranties, register unit, keep installation certificates, and use approved installers; unauthorized repairs void coverage and harm safety. Note resale implications: document firmware, commissioning logs, and serials.

Confirm compatibility, protection, comms, and DNO approvals; document installs to safeguard warranties and future resale.

- Validate vehicle charging curves, schedules, and lock modes.

- Avoid RF congestion; site the hub and antenna carefully.

- Plan load management with priority circuits and diversity.

Conclusion

You’re ready to spec and install Zappi confidently: align with IEC 61851 Mode 3, BS 7671:722, RCD Type A with 6 mA DC detection, PEN‑fault protection, and CTs for solar/load control. Confirm supply capacity, earthing, and OCPD upfront; commission via app/OCPP with ECO/ECO+ verified. Expect £1,100–£2,900 all‑in depending on civils and phases. One useful metric: about 80% of EV charging happens at home, so safe, standards‑compliant design and documentation protect users, property, and warranties long‑term.