By coincidence, your service panel sits near the garage where you want a Tesla outlet, but proximity alone won’t make it safe. You’ll verify service capacity, pull permits, and size a two‑pole breaker at 125% of the continuous EV load. Then you’ll choose NEMA 14‑50 or 6‑50, copper conductors, and GFCI/weatherproofing per your AHJ. Done right, you avoid overheated wires, nuisance trips, and failed inspections—here’s how to proceed.

Key Takeaways

- Assess charging needs, location, cable routing, indoor/outdoor rating, GFCI as required, and ensure cord reach and safe mounting.

- Obtain permits, follow local NEC edition, perform dwelling load calculation, treat EV load as continuous at 125%, plan upgrades if service undersized.

- Choose NEMA 14-50 (neutral) or 6-50 (no neutral), 50A 2‑pole breaker, #6 Cu THHN/THWN‑2 conductors; evaluate voltage drop and temperature ratings.

- De‑energize panel, install conduit and box, land two hots on two‑pole breaker, ground to bar, neutral only if required, mount and label receptacle.

- Test 240V hot‑hot and 120V hot‑ground, torque lugs, load‑test at 80% of breaker rating, monitor temperatures, schedule inspections.

Assess Your Charging Goals and Site Conditions

How often will you charge at home, and how fast do you need to recover daily miles? Define your daily range needs, then match them to realistic charging rates: a 240V, 32–40A EVSE adds 25–35 miles per hour. Decide whether overnight replenishment suffices or you need quick top‑ups.

Assess the site. Map the panel-to-outlet path to minimize cable length and avoid heat, moisture, or physical damage. Choose an indoor or outdoor location with appropriate NEMA enclosure and GFCI protection in garages. Plan parking orientation so the Tesla charge port and cord reach without strain; verify cord length and routing to avoid trip or crush hazards. Provide sturdy mounting, drip loops, and adequate lighting. Use a dedicated circuit and space for safe cord management practices.

Permits, Code Compliance, and Load Calculations

Before you pull a single cable, secure a permit and align your design with your Authority Having Jurisdiction’s (AHJ) adopted NEC edition. Verify local amendments, Permit timelines, and fees. Perform a dwelling service load calculation per NEC 220; include existing general lighting, small-appliance circuits, fixed appliances, HVAC, and treat the EV load as continuous at 125%. Document conductor ampacity, temperature ratings, and terminations to match the lowest-rated component. Schedule inspections and be on site to answer questions. Retain records for approval.

Secure permits, align with AHJ’s NEC; calculate loads, treat EV at 125%, document ampacity, schedule inspections, retain records.

- Confirm Inspection requirements, rough-in and final, and required accessibility clearances.

- Prepare a one-line diagram, panel schedule, and load calc worksheet for submittal.

- Check service capacity; plan upgrades if calculated demand exceeds service rating.

- Maintain working space, grounding, bonding, and GFCI/AFCI coordination per code.

Selecting the Outlet, Breaker, and Wire for Your Circuit

With your permit and load calculation complete, choose the receptacle configuration and size the breaker and conductors for a continuous EV load at 125%. Match Tesla current, run length, and Plug compatibility. For 32A mobile charging, use a 50A 2‑pole breaker and a 50A receptacle. Copper #6 AWG (or aluminum #4) is typical; select THHN/THWN‑2. NEMA 14‑50 needs hot‑hot‑neutral‑ground; 6‑50 omits neutral. Provide GFCI where required. Torque lugs per listing, and evaluate voltage drop. Confirm Conductor materials and terminations are listed as compatible. Use a common-trip, 2-pole breaker; match temperature rating of terminations (60°C or 75°C). Check labeling again.

| Receptacle | Circuit notes |

|---|---|

| NEMA 14-50 | 50A, 4-wire, GFCI, neutral present |

| NEMA 6-50 | 50A, 3-wire, no neutral, GFCI |

| NEMA 14-30 | 30A, 4-wire; limit to 24A continuous |

Installation Procedure From Panel to Receptacle

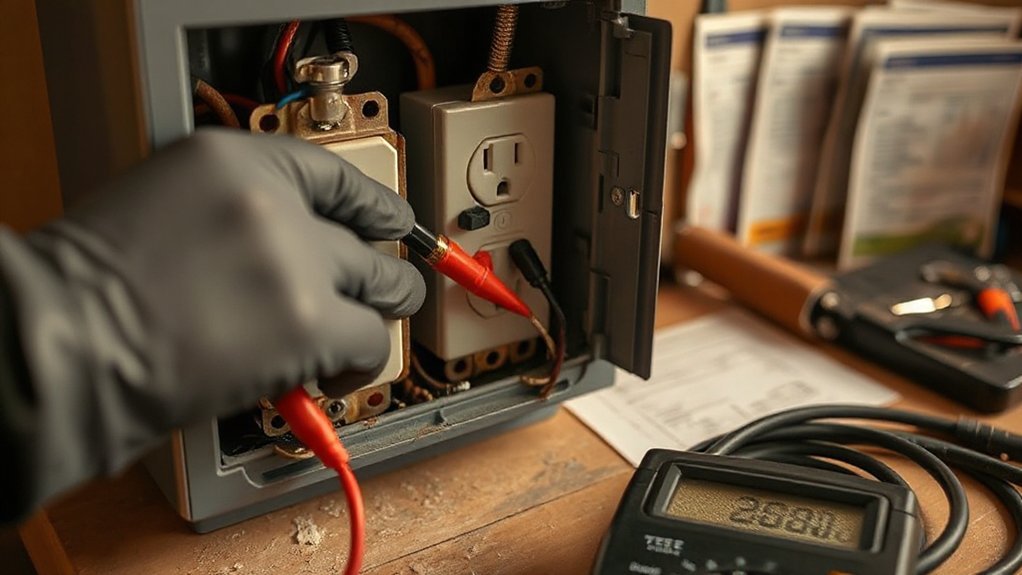

Once the circuit is specified and permitted, de-energize the service equipment, apply lockout/tagout, and verify absence of voltage with a properly rated meter. Route NM-B or THHN in conduit per listing; perform knockout preparation on the panel and install a listed connector with bushing. Land the two hots on the new two-pole breaker and the equipment grounding conductor on the grounding bar; neutral only if the receptacle requires it. Torque terminals to manufacturer specs.

De-energize, lockout/tagout, verify voltage; route NM-B/THHN, install bushing; land hots, ground, neutral if required; torque to spec.

- Mount the box at ADA-safe height; complete box mounting with appropriate fasteners.

- Pull conductors with slack; protect bends; cap unused neutrals.

- Terminate receptacle: tighten side lugs, bond yoke, install cover.

- Label breaker and receptacle “EV Charging—240V—Amps.”

Reinstall the panel dead front securely before energizing. Verify required clearances and cord reach.

Costs, Testing, Troubleshooting, and When to Hire an Electrician

Although a DIY install can be straightforward, you should budget realistically and verify performance methodically: expect $150–$500 for materials (box, receptacle, cover, conduit/wire, two‑pole breaker, GFCI protection where required by NEC 210.8/625), $50–$300 for permits, and $300–$1,200 for labor if you hire it out, with service or panel upgrades running $1,500–$4,000+. Lock out, remove cover, and torque lugs to spec; then measure hot‑hot at 240V ±5%, hot‑ground at 120V, and confirm polarity and equipment grounding. Load‑test the circuit at 80% of breaker rating per NEC 625. Monitor temperatures with an IR thermometer. If you see nuisance trips, voltage sag, or heat, stop and diagnose with diagnostic tools. Hire an electrician for service upgrades, aluminum feeders, detached structures, or suspect panels. Budget ongoing operational costs.

Conclusion

You’ve planned, permitted, and sized like a pro. Now finish strong: install the two‑pole breaker at 125% of continuous EV load, land correctly sized copper conductors, bond/ground per code, and use a listed NEMA 14‑50 or 6‑50 in the right enclosure. Label the circuit, add GFCI if required, and pass inspection. Then test voltage, polarity, and grounding, and monitor the first charges for heat or nuisance trips. Skip any step and the electrons will revolt—spectacularly.