You’re considering a 50 kW DC fast charger for 2025, so quantify what it really delivers: roughly 10–40 miles in 15–30 minutes, dependent on vehicle curve and temperature. Plan for NEC/ADA compliance, ISO 15118/OCPP 2.0 support, utility coordination, and cybersecurity. Budget beyond hardware—make‑ready, trenching, and potential transformer upgrades drive cost. Manage demand charges with load controls or batteries. Ready to see model-specific times, site power needs, and permitting traps?

Key Takeaways

- Expect 10–80% in 35–95 minutes, varying by battery size and taper; 50 kW nameplate is limited by vehicle, temperature, and load sharing.

- 2025 costs: hardware $15k–$30k per 50 kW unit; turnkey installed $40k–$100k+, heavily driven by civil works, utility upgrades, and incentives.

- Plan 65–75 kVA per charger including auxiliaries; perform NEC Article 220 load calcs, protective device coordination, and confirm short-circuit current ratings.

- Engage the utility early for transformer capacity, metering class, and make-ready; approvals and upgrades commonly take 4–18 months.

- Specify dual CCS/NACS, ISO 15118-20 and OCPP 2.0.1, NEMA 3R/4 enclosures, ADA access, bollards, Ethernet/LTE, and remote diagnostics with signed firmware.

What a 50 Kw DC Fast Charger Really Delivers

Although the nameplate says 50 kW, a DC fast charger delivers that power only when the vehicle, temperature, and charger all permit it. You’ll see power limited by your pack’s voltage window, BMS current caps, SOC taper, and cable or connector temperature. If the site power is load-shared, per-stall output can drop below 50 kW. Cold packs restrict current; hot packs trigger thermal derates. Firmware may enforce grid-demand or utility curtailment limits. Verify connector standard, rated current, and cable cooling; use only undamaged equipment and follow lockout-tagout when servicing. Plan for code-compliant clearances, bollards, signage, and lighting that support safety, driver satisfaction, and location desirability. Monitor logs and OCPP alerts to detect faults, nuisance trips, or grounding issues. Perform periodic torque checks on lugs.

Real-World Charge Times by EV Model

Real-world charge time at a 50 kW DC fast charger depends on each model’s charge curve, pack voltage, BMS current limits, SOC taper, and thermal state, plus any site load-sharing or firmware caps. You’ll see sub-50 kW plateaus on cars with lower pack voltage or conservative current limits, especially above 60% SoC. For planning, budget from 10% to 80% as follows: small packs (40–55 kWh) about 35–55 minutes; midsize (60–80 kWh) about 45–70 minutes; large (90–120 kWh) about 60–95 minutes, assuming stable input power.

SoC effects dominate taper: power often falls by 30–70% past 60–70% state of charge. Thermal management matters: precondition the pack, avoid repeated back‑to‑back fast sessions, and respect manufacturer limits to protect cells and prevent fault codes. Monitor connector temperature closely.

Hardware Options and 2025 Standards (CCS, NACS, ISO 15118)

Standards-driven hardware choices determine what a 50 kW DC fast charger can safely and legally deliver in 2025. For plug interfaces, specify dual CCS and NACS to cover North American fleets; select UL-listed couplers with robust Connector ergonomics, locking actuators, and ≥10,000 mating cycles. Use 95–125 A rated cables with verified Thermal management (air or liquid) and conductor temp sensors to prevent derating. On the control stack, enable ISO 15118-2/-20 for Plug & Charge, smart charging, and certificate-based cybersecurity; keep DIN 70121 for legacy vehicles. Choose PLC modems certified to CharIN test cases. Integrate DC leakage detection, isolation monitoring, emergency stop, and contactors rated for 1000 VDC. Specify NEMA 3R/4, IK10 enclosures, UV-stable cables, clear labeling, and a revenue-grade meter; support OCPP 2.0.1 backend.

Site Power Requirements and Utility Coordination

How do you right-size site power so a 50 kW DC charger runs safely and passes inspection? Start with a load calculation per NEC Article 220 and demand factors for coincident loads. Confirm available short-circuit current, fault duty, and protective device ratings. For a single 50 kW unit, plan roughly 65–75 kVA including auxiliary loads and power factor. Verify service voltage, phase, and utility metering requirements. Coordinate early with the utility on transformer capacity, service lateral, and metering class. Request written Utility Timelines for design, permitting, and energization. If upgrades are required, obtain cost estimates, refundable allowances, and schedule impacts. During Contract Negotiation, define scope, easements, make-ready responsibilities, and outage windows. Document one-line diagrams and equipment submittals for approval before issuance of service authorization.

Installation Scope: Civil, Electrical, and Networking

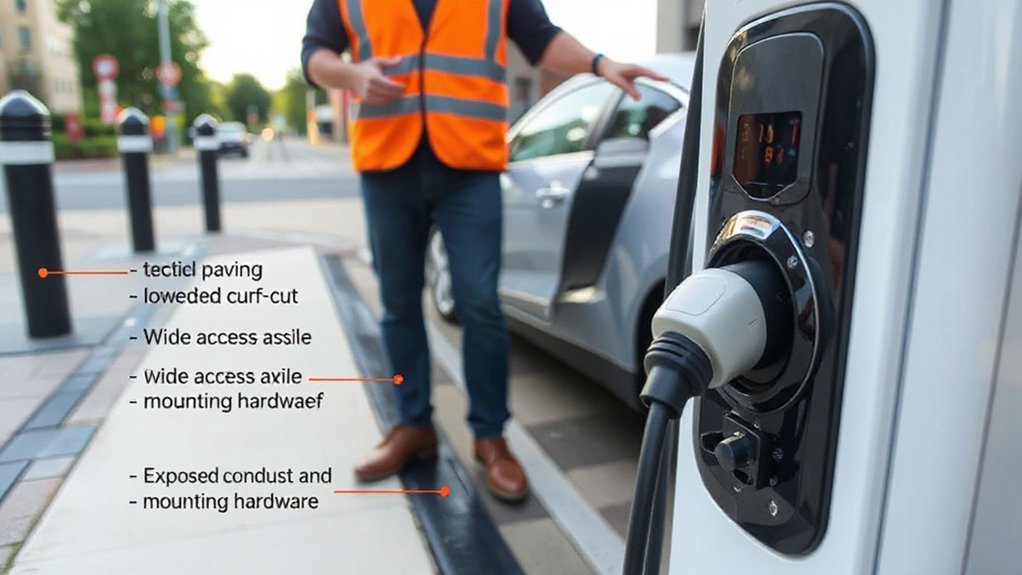

You’ll plan site works and trenching per local code: confirm utility locates, ADA access, drainage, bollard placement, foundation specs, and conduit depth/segregation with proper warning tape. You’ll integrate the power supply with code-calculated feeder sizing, switchgear, protection coordination, grounding/bonding, fault-current rating, and voltage-drop limits to safely serve a 50 kW load. You’ll establish connectivity and commissioning by provisioning secure Ethernet/LTE backhaul, configuring OCPP, validating EMI limits, and executing acceptance tests, safety interlocks, and firmware updates.

Site Works and Trenching

Before breaking ground, secure permits, complete utility locates, and mark the excavation limits and tolerance zones; establish traffic control and trench safety per MUTCD and OSHA 29 CFR 1926 Subpart P (sloping/shoring, ladder egress, dewatering as needed). Perform archaeological monitoring where required and deploy erosion control BMPs to protect inlets and soils. Lay out trench alignment; meet minimum cover per NEC 300.5, maintain power–data separation, and choose Schedule 40/80 or concrete encasement in vehicle areas. Control bend radius per NEC Chapter 9; place warning tape and tracer wire. Install pull boxes at workable intervals, mandrel/brush conduits, and leave pull strings. Use sand bedding; compact lifts to 95% per ASTM D1557. Maintain ADA access, manage dewatering, and restore surfaces per permit, and record as-builts accurately.

Power Supply Integration

Once civil works are ready, integrate the power supply by coordinating utility service, transformer or secondary source, service equipment, and network backhaul in accordance with NEC 625, utility standards, and the AHJ.

Verify service capacity via load calculations per NEC 220; confirm available fault current and SCCR of equipment. Specify transformer kVA, voltage, impedance; provide coordinated OCPD, SPD, and visible-lockable disconnects. Install feeders in listed raceways; size conductors for voltage drop to maintain 50 kW at nameplate. Implement grounding and bonding per NEC 250; connect GECs and assure equipotential plane at pedestal. If a generator or PV supplies the site, provide UL 1741-SA interconnection, anti-islanding, and Microgrid synchronization via a listed controller and transfer scheme per NEC 705. Include Harmonic mitigation to limit THDi.

Connectivity and Commissioning

With power integrated to code, establish connectivity and execute commissioning that binds civil, electrical, and networking scopes into a safe, operable 50 kW EVSE. Verify pad anchors, bollards, ADA clearances, and sealed conduits; confirm bonding jumpers, ground resistance, surge protection, and correct phase rotation. Configure the controller, set nameplate limits, and validate insulation resistance, isolation monitoring, RCD/GFCI trip, and CP/PP signaling with a test box.

You’ll provision networking via Ethernet or LTE: assign static IPs or DHCP reservations, segment with VLANs, enforce TLS, and whitelist the OCPP endpoint. Enable remote diagnostics, logs, and alerts; update firmware; test session start/stop, payment, and fallback logic under power loss. Document serials, SIM/IMEI, as-builts, and passwords in a handover. Deliver operator training on safety, lockout/tagout, reboot, and escalation.

Total Cost of Ownership: Capex and Opex Breakdown

Clarity on total cost of ownership starts by separating capital expenditures (CapEx) from operating expenses (OpEx) for a 50 kW DC fast charger. CapEx covers dispenser, power module, pedestal, liquid‑cooled cables, payment terminal, bollards, signage, civil works, panelboard, transformer or service lateral, trenching, and permits. Specify NRTL-listed equipment and NEC-compliant conduit, grounding, and fault protection. Document commissioning and as-builts. Establish depreciation schedules aligned with tax rules; model residual value and warranty coverage. Include design, engineering, interconnection studies, and contingency.

OpEx includes kWh energy costs, network and software subscriptions, cybersecurity monitoring, payment processing, preventive maintenance, periodic testing, calibration, cleaning, site lease, inspections, spare parts, vandalism repairs, call-center support, and insurance premiums. Track uptime SLAs, spare rectifiers, and firmware updates. Budget regulatory compliance audits and training.

Demand Charges, Load Management, and Batteries

Although demand charges can dwarf energy costs, you can control them with code-compliant load management and, where justified, a battery energy storage system (BESS). Deploy demand limiting in your EVSE controller and size the BESS to shave peaks during the utility’s demand window. Use Tariff Forecasting to schedule precharge and dispatch while protecting Battery Degradation through conservative depth‑of‑discharge and temperature management.

- Audit load: log kW profiles per charger, diversity factors, and site baselines.

- Set limits: implement UL-certified load sharing, phased starts, and soft limits tied to feeder capacity.

- Optimize BESS: right-size kW/kWh, round‑trip efficiency, and inverter overload capability.

- Operate safely: enforce NEC-compliant interlocks, islanding protection, and SOC reserves for outages.

Verify results monthly; tune algorithms, seasons, and tariffs as rates fluctuate.

Permitting, Codes, and Accessibility

Before you break ground, coordinate with the authority having jurisdiction (AHJ) to map the permits, codes, and accessibility requirements for a 50 kW DC fast charger. Submit sealed plans: site layout, one-line diagram, load calculations, short-circuit/arc-flash data, and equipment cut sheets. Design to NEC 625, 110.26 clearances, and fire code; specify bollards, working space, and labeling. Address ADA compliance: accessible route, slopes ≤1:20, 36 in min clear width, 30×48 in clear floor area, and connector reach.

| Item | Requirement |

|---|---|

| Electrical permit | NEC 625 compliance, utility fault-current available |

| Civil permit | Trenching, resurfacing, traffic control plan |

| Accessibility | Signed accessible stall, route, reach ranges |

| Protection | Wheel stops, bollards, guard rails |

Plan Inspection timelines with AHJ: trench/rough, service release, and final. Provide tests, grounding continuity, OCPD settings, and as-builts.

Incentives, Rebates, and Tax Credits

You can cut total installed cost with federal tax credits, state and local rebates, and utility incentive programs for 50 kW DC fast chargers. Confirm eligibility, caps, stacking rules, and documentation timelines, and verify UL/ETL‑listed equipment is installed per NEC by a licensed contractor to satisfy program requirements. Coordinate early with your utility on make‑ready, demand‑charge mitigation, metering, and any networked reporting needed for verification and safe interconnection.

Federal Tax Credits

While project economics matter, federal incentives can materially lower the installed cost of a 50 kW DC fast charger when you meet specific eligibility rules. The primary mechanism is IRC §30C, updated by the IRA; understanding its Legislative history helps you scope compliant designs and budgets.

- Verify site eligibility: property must be in an eligible census tract under §30C maps; document this.

- Determine rate: 6% base or 30% with prevailing wage and apprenticeship; apply the $100,000-per-item cap.

- Use Credit transferability: if you lack tax liability, transfer the credit for cash; keep assignment and attestation records.

- Engineer for compliance: specify UL‑listed equipment, NEC 625 clearances, labeled disconnects, and commissioning logs to support audits.

Coordinate with your tax counsel and maintain evidence.

State and Local Rebates

Because state, local, and utility programs can offset both charger hardware and make‑ready costs, map all applicable rebates for your 50 kW DCFC early and design to their rules. Confirm eligibility by site type, power level, and public access hours. Many state or city rebates require ADA-compliant layouts, UL-listed equipment, NEC Article 625 conformance, and inspection sign-off. Document load calculations, one-line diagrams, and trenching plans; some programs reimburse make-ready only. Verify stacking rules with federal credits to avoid double-dipping. Track deadlines, pre-approval, and commissioning proofs. Use outreach strategies to meet scoring: publish pricing, uptime, and accessibility plans. Address equity impacts by prioritizing disadvantaged-community siting, multilingual signage, and transparent pricing. Maintain prevailing-wage and Buy America documentation when specified. Build a compliance matrix and assign responsibilities.

Utility Incentive Programs

Utility incentive programs can offset both make-ready and operating costs for a 50 kW DCFC and complement state and local rebates. To capture value safely, coordinate with your utility early, align design loads, and document metering, grounding, and fault protection per code.

- Verify Program Eligibility: confirm customer class, charger power, site host status, and make-ready scope qualify; note demand-response or managed charging requirements.

- Map Application Timelines: pre-approval windows, construction deadlines, inspection milestones, and energization dates; build float for transformer lead times.

- Optimize rate selection: evaluate EV-specific tariffs, demand charge holidays, and TOU alignment; size buffers for seasonal peaks.

- Document compliance: maintain as-builts, commissioning reports, load calculations, and UL/NRTL listings; keep O&M and outage procedures.

Stack incentives, rebates, and tax credits, but avoid double-dipping conflicts.

Future-Proofing and Common Pitfalls to Avoid

Even as standards evolve, you can future‑proof a 50 kW DC fast charger by selecting open, upgradeable hardware and software that meet current and emerging protocols.

Specify OCPP 2.0.1, ISO 15118-20, and open metering APIs. Choose modular power stacks, swappable cables, and firmware OTA with signed updates. Validate electrical clearances, seismic anchoring, and environmental resilience ratings (NEMA/IK/IP). Coordinate utility capacity, load management, and cybersecurity logging. Avoid pitfalls: proprietary locks, undersized conduits, no spare fiber, weak grounding, and skipped commissioning. Document as-builts and maintenance intervals; review insurance implications and warranty conditions. Plan spares and remote diagnostics from commissioning.

| Area | Risk | Mitigation |

|---|---|---|

| Grid | Voltage sag | Add UL 1741-SB inverter, kVAR support |

| Site | Corrosion | Select stainless, sealed glands, drains |

| Cyber | Rogue access | Enforce mTLS, rotate keys, syslog |

Conclusion

You’ve seen how a 50 kW DCFC really performs: roughly 10–40 miles in 15–30 minutes, contingent on vehicle, temp, and SOC. Treat the project like a substation in miniature: engineer loads, coordinate utility, meet ADA clearances, and commission to spec. Choose CCS/NACS hardware with ISO 15118 and OCPP 2.0. Manage demand with smart profiles or batteries. Document cybersecurity. Chase incentives early. If you build the backbone right, uptime hums like a well‑tuned inverter under load.