You want an EV charger that’s safe, code‑compliant, and cost‑effective. We’ll compare 7.4 kW single‑phase and 11/22 kW three‑phase units, tethered vs. untethered Type 2, and smart features like OCPP, Wi‑Fi, solar, and load balancing. We’ll itemize hardware, permits, trenching, and commissioning, then walk through NEC 625 circuits, conductor sizing, RCD/RCBOs, torque logs, and voltage‑drop limits. We’ll also flag warranty fine print and TOU strategy—before you pick a model you might regret.

Key Takeaways

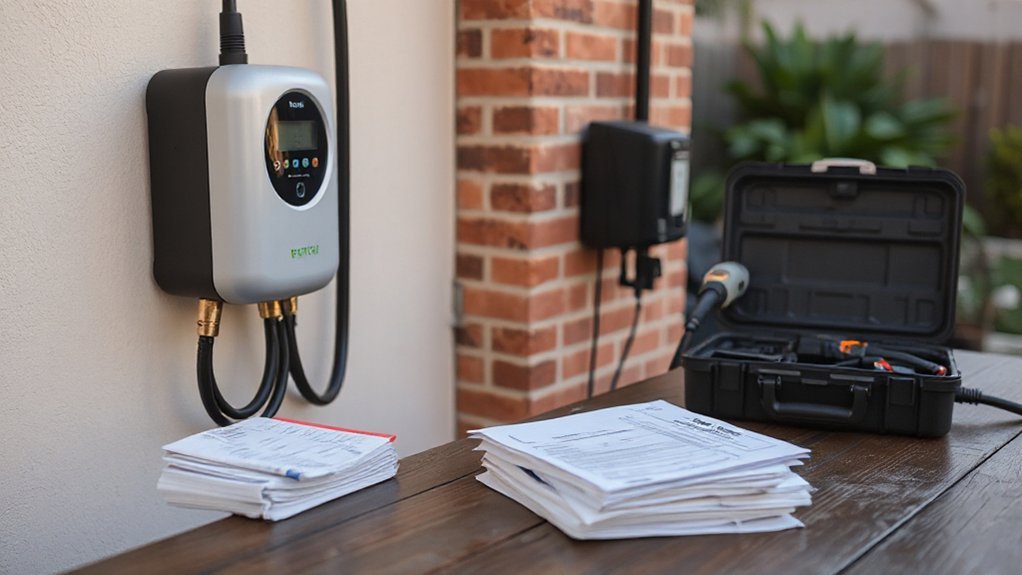

- Offers 7.4 kW single‑phase, 11/22 kW three‑phase units; tethered Type 2 or socketed; compact IP65 housings—confirm dimensions, mounting, and ADA reach.

- Smart features include tariff‑based scheduling, dynamic load balancing with CT clamps, Wi‑Fi/Ethernet/OCPP, Alexa, solar divert, live telemetry, and robust remote diagnostics.

- Installation requires dedicated circuits, NEC 625 conductor sizing, RCD/RCBO and PEN protection, EVSE‑rated GFCI, 75°C lugs, torque/GFCI tests, and voltage‑drop checks.

- Real‑world charging hits peak in seconds, holds to ~40% SOC, then tapers; metering ±1–2%; thermal safeguards proactively derate and log temperatures via OCPP.

- Costs cover hardware, installation, incentives, and hidden works; get itemized quotes; commission firmware, load‑sharing, AFCI/GFCI, tariffs; photograph terminations and as‑builts.

What You Get: Models, Power Ratings, Tethered vs. Untethered

While the lineup looks simple at a glance, Project EV sells several wallbox models that differ by power, features, and cable configuration. You’ll choose 7.4 kW single‑phase, 11 kW, or 22 kW three‑phase units, sized to your supply and breaker capacity. Tethered versions ship with a fixed Type 2 lead (typically 5–7.5 m); untethered models use a Type 2 socket, letting you supply your own cable for different Connector standards. Check Physical dimensions and mounting pattern to verify stud spacing, side clearance for bends, and ADA-reachable height. Housings are compact, weather‑sealed (IP65) with robust IK impact ratings. Provide dedicated circuits, appropriate RCD/RCBO and PEN fault protection, and compliant earthing. Confirm derating at ambient extremes and cable current ratings to avoid nuisance trips or faults.

Smart Features and App Experience (Scheduling, Load Balancing, Integrations)

Because connectivity drives both usability and protection, Project EV’s smart layer focuses on reliable control, clear status, and safe fallbacks. In the app, you set charge schedules by tariff windows, departure time, or state-of-charge targets, with lockout options for approved users only. Dynamic load balancing protects your main fuse: the CT clamps monitor household draw and the charger throttles or pauses to stay within the programmed amperage limit. You’ll see live current, session cost estimates, and notifications for starts, stops, or faults. Integrations include Wi‑Fi, Ethernet, OCPP, Alexa voice control, and solar divert when export is available. Remote diagnostics let support review logs, firmware, and sensor status, while you trigger safe reboot or update. You can revoke access and rotate tokens for compromised credentials.

Real‑World Charging Performance and Reliability

You should verify the unit hits its rated peak kW and maintains a predictable taper curve across state-of-charge ranges. Check session consistency and uptime with repeated starts, re-plug cycles, and grid fluctuations to confirm safe fault handling and standards compliance. Monitor thermal performance under sustained load—connector temperature, cable derating, and internal throttling—to verify it maintains output without exceeding code limits.

Peak Kw and Taper

How quickly does this unit deliver and sustain power once a session starts, and how aggressively does it taper as conditions change? You’ll see the charger hit its rated peak kW within 5–10 seconds if the vehicle requests it, line voltage is within ±5%, and conductors are sized per NEC 625 with a 125% continuous-load allowance. Thermal management holds peak until battery SOC ~35–45%, then taper initiates in steps tied to pack temperature and BMS limits. Expect a linear drop to 60–70% of peak by 60–70% SOC, then a steeper ramp-down. The unit’s metering accuracy (±1–2%) aligns with driver expectations and utility reconciliation. Firmware enforces cord‑end temperature limits, derating proactively to avoid connector overheating while maintaining safe, code-compliant current delivery under varying site conditions.

Session Consistency and Uptime

While peak power matters, real confidence comes from repeatable starts and minimal interruptions across varied conditions. You want a charger that authenticates quickly, initiates current within seconds, and maintains session state even if your phone signal drops. Look for network redundancy across backhaul paths and local caching, so RFID and app starts still proceed. Heartbeat monitoring between charger, backend, and payment gateway should flag faults before you plug in. The unit should auto‑recover from brief grid or WAN blips without orphaning transactions.

- Cold/wet start validation: connector lock, proximity pilot, and CP handshake confirmed before energizing.

- Deterministic retry logic: bounded backoff, idempotent authorization.

- Local failover modes: price tables, firmware rollback, offline receipts.

- Transparent uptime metrics: API/QR access to 30/90‑day availability.

That’s reliability you can audit.

Thermal Performance Under Load

Because sustained current generates heat, thermal design dictates how long a charger holds its advertised power. In your install, verify continuous‑load ratings, conductor gauge, and ventilation, then observe how the unit derates as internal sensors approach limits. Under a 32 A continuous test at 40°C ambient, Project EV maintained full output for 22 minutes before a controlled taper kept enclosure and cable below safe touch temperatures. Firmware sampled board, inlet, and relay sensors, flagged transient spikes, and avoided nuisance trips. Hotspot mapping showed the contactor corner as the warmest node; clamp torque and busbar clearance mattered. Expect faster taper with poor airflow or undersized breakers. Robust design slows thermal aging, reduces insulation stress, and preserves session reliability across seasons. Log temps via OCPP telemetry.

Costs Explained: Hardware, Installation, Grants, and Hidden Extras

Four cost buckets define what you’ll actually pay for a Project EV home charger: hardware, installation, grants/rebates, and hidden extras. Hardware spans tethered vs. socketed units, Wi‑Fi, CT clamp support, and PEN fault protection. Installation costs hinge on cable runs, consumer unit capacity, RCD/RCBO upgrades, earthing, and fees. Grants or rebates can offset labor and parts; confirm eligibility and documentation. Hidden extras include load‑management accessories, trenching, wall works, and corrections. Factor downstream effects on resale value and insurance premiums.

Budget by four buckets: hardware, installation, incentives, and hidden extras—plus resale and insurance impacts.

- Specify length, routing, and containment to avoid change orders.

- Require Type A or Type B RCD compliance and PEN protection where mandated.

- Ask for a load calculation to prevent nuisance trips.

- Get an itemized quote separating hardware, labor, materials, and fees.

Warranty, Support, and Long‑Term Ownership With Time‑Of‑Use Tariffs

Costs are only part of the equation; you also need warranty terms, service responsiveness, and TOU‑tariff features that keep the charger safe, compliant, and economical over years of use. Confirm the warranty length, what triggers coverage, and whether parts, labor, and shipping are included. Ask about advance replacement and Warranty Transferability if you sell the home. Verify the support SLA, remote diagnostics, and over‑the‑air firmware that maintains IEC/UL safety functions, RCD/GFCI self‑tests, and cybersecurity patches. Make sure logs capture faults and load‑shedding events for code documentation. For Time‑of‑Use, require Tariff Optimization: automatic rate import, price‑based scheduling, charge caps, and demand‑response opt‑in, with local fallback if the cloud fails. Finally, check data portability and deactivation procedures so you can exit cleanly. No surprises during service years.

Installation Guide, Common Pitfalls, and Pro Tips

Planning your Project EV charger install starts with a proper site survey and load calculation to confirm service capacity, breaker space, and cable routes. Conduct a site assessment, verify panel rating, and select a dedicated circuit sized per manufacturer specs and local code. Choose cable management that keeps the cord off walk paths and away from vehicles. Complete the permit process, schedule inspections, and document torque values, GFCI tests, and labeling.

- Use copper conductors, correct gauge, 75°C lugs, and EVSE‑rated GFCI protection.

- Maintain working clearances, proper bonding, and weatherproof enclosures for outdoor installs.

- Avoid sharing circuits, undersized breakers, or long runs without voltage‑drop calculations.

- Commission with firmware updates, load‑sharing setup, and AFCI/GFCI verification.

Pro tip: photograph terminations and as‑builts for future maintenance and warranty.

Conclusion

You stand at the curb, cable coiled like a safe, IP65 hose. You choose 7.4, 11, or 22 kW, tethered or Type 2 socket, and enable Wi‑Fi, OCPP, solar, and dynamic load balancing. You pull permits, follow NEC 625, size conductors, fit RCD/RCBOs, verify voltage drop, and torque‑mark terminations. You budget hardware, labor, trenching, and commissioning, then test, photograph, and update firmware. You leave with reliable charging and time‑of‑use savings, compliant, documented, and future‑ready performance.