If you’re planning a Tesla Wall Connector in 2025, expect total installed costs from about $525 to $6,500, driven by hardware, electrician labor, permits, trenching, and potential service upgrades. You’ll need NEC‑compliant wiring, load calculations, and inspections to protect warranties and qualify for incentives. Smart load management and utility make‑ready funds can trim the bill—if you choose the right setup next.

Key Takeaways

- Hardware price: Gen 3 $475, Universal $595; optional pedestal $425, organizer $35.

- Typical install costs by scenario: short run $300–$900; standard garage $900–$1,800; exterior pedestal $1,800–$4,500; complex upgrades $3,000–$6,000+.

- Soft costs: permits $50–$350+, inspections; electrician labor $75–$200/hr depending on license and complexity.

- Electrical requirements drive sizing costs: 48A output needs 60A circuit, #6 copper, 2‑pole breaker, NEC 625/220 compliance.

- Incentives can reduce net cost: many programs offer $200–$1,500, requiring permits, UL-listed equipment, and sometimes managed charging enrollment.

What You’ll Pay for the Wall Connector in 2025

How much will it run you in 2025? Expect Tesla’s Wall Connector to list at retail pricing around $475 for the standard Gen 3 (24‑ft cable) and about $595 for the Universal variant with integrated J1772. Budget sales tax and shipping, which vary by state. Optional hardware includes a pedestal (~$425) and a cable organizer (~$35). Units are UL listed, 60‑A max input with up to 48‑A output, Wi‑Fi for firmware updates, and built‑in GFCI—features that support NEC‑compliant installations when configured correctly. Warranty options: Tesla’s residential limited warranty is typically 4 years; commercial use is shorter. Extended coverage from Tesla isn’t common; third‑party plans may exist. Verify amperage settings, circuit rating, and load‑sharing needs before purchase to match your service and panel capacity limits.

Labor, Permits, and Inspection: Typical Line-Item Costs

You should budget for licensed electrician labor, which varies by market, circuit ampacity, panel capacity, and any required code upgrades (load calculations, GFCI protection, conduit). You’ll also pay permit application fees set by your local authority having jurisdiction, often tiered by project valuation or circuit size. Finally, expect a final inspection charge—sometimes bundled with the permit—to verify NEC/local compliance and document the installation for utility or warranty purposes.

Electrician Labor Rates

Most installations break down into a few predictable line items: electrician labor, permit fees, and inspection. For labor, you’ll typically pay by the hour, driven by license tier, EVSE experience, and regional market rates. Expect journeyman rates around $75–$150/hr and master electrician rates around $100–$200/hr, with apprentices billed lower under supervision. Complexities like long conduit runs, panel derating, or service upgrades add hours.

- Verify certification levels and career pathways; request license numbers and insurance.

- Ask for a site-walk quote with estimated hours, materials, and scope exclusions.

- Confirm EV charger experience, torque specs, GFCI/AFCI, and load calcs per NEC 625/220.

- Clarify scheduling: standard vs after-hours, travel, and change-order rates.

Get a written labor-only line item and require code references in the proposal. That protects scope clarity.

Permit Application Fees

Why do permit application fees vary so widely for a Tesla home charger? Your jurisdiction sets fees based on scope: panel upgrade, new circuit amperage, trenching, or exterior runs can trigger plan review and zoning checks. You’ll pay more if the authority requires load calculations, site plans, or expedited processing; some add application surcharges for online portals or credit card payments. Typical ranges are $50–$350, but complex service upgrades can push higher. Ask whether EV-specific fee waivers, low‑income reductions, or utility-sponsored rebates apply. Submit a complete package: manufacturer specs, one-line diagram, load calc, conductor sizes, breaker rating, and mounting location. Verify licensed electrical contractor, permitting agent authorization, and NEC/local amendments. Accurate documents prevent resubmittals, delays, and change-order costs. Budget accordingly and confirm timelines upfront.

Final Inspection Charges

After the permit’s approved, the project wraps with a final inspection and closeout charges that aren’t always baked into the application fee. Expect the authority having jurisdiction to verify NEC 2023 compliance, bonding, labeling, breaker rating, conductor size, GFCI protection, and load calculations. You’ll also pay administrative items tied to scheduling and document closeout. If you miss an appointment window or fail an item, you could see re‑inspection late fees. Ask about waiver options for first-time corrections or consolidated site visits. Budget these line items to avoid delays and keep your charger activation on schedule.

- Final inspection dispatch and processing: $50–$200.

- Re-inspection fee (if corrections required): $75–$250.

- Closeout documentation (as-builts, photos, affidavit): $25–$150.

- Utility coordination or meter seal reset: $0–$150.

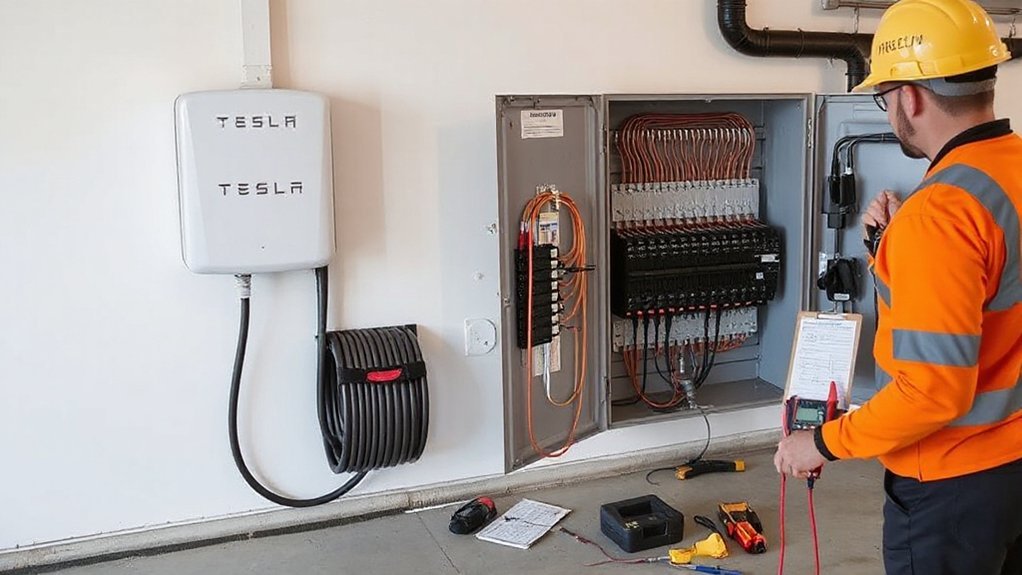

Electrical Requirements: Circuits, Load Calculations, and Panel Capacity

You’ll size the dedicated circuit to the EVSE’s continuous load using the 125% rule (e.g., 60A breaker for 48A charging, 50A for 40A), and set the Wall Connector accordingly. You’ll match conductor gauge and breaker type to the selected amperage and manufacturer specs, and keep the circuit dedicated. You’ll assess panel capacity with an NEC 220 load calculation, confirm available amperage and breaker spaces, and plan an upgrade if the bus or service rating is insufficient.

Dedicated Circuit Amperage

Because EV charging is a continuous load, size the dedicated branch circuit at least 125% of the charger’s maximum continuous output per NEC 625—meaning a 48A Wall Connector setting requires a 60A breaker, 32A requires 40A, and 16A requires 20A. Use a 2-pole breaker, copper conductors, and 75°C–rated terminations; match conductor gauge to breaker rating. Keep the circuit dedicated to avoid nuisance trips, EMI effects, and unsafe Appliance interactions.

1) Conductor sizing: 60A -> #6 Cu THHN; 40A -> #8 Cu; 20A -> #12 Cu (verify local amendments).

2) Breaker type: standard thermal-magnetic; GFCI not required for hardwired Wall Connector (integral protection).

3) Grounding: bond equipment grounding conductor; keep neutral isolated (not used).

4) Installation: use continuous conduit support, proper torque, labeling at disconnect.

Panel Capacity Assessment

Before adding a Tesla Wall Connector, verify your service and panel can carry the additional continuous load using an NEC Article 220 load calculation. Treat EV charging as a 125% continuous load per NEC 625; verify main breaker, bus, and feeder ampacity. If calculated demand exceeds service, plan a panel upgrade or an EV energy management system.

| Service size | Typical outcome |

|---|---|

| 100A | Needs management or upgrade |

| 125A | Borderline; calculation decides |

| 150A | Usually acceptable |

| 200A | Often OK, no upgrade |

Keep documentation for permit review. Using a listed 60A circuit for a 48A charger preserves compliance, limits trips, and supports insurance implications. Capacity improves resale impact.

Common Installation Scenarios and Price Ranges

Three patterns cover most Tesla home charger installs, with installed costs (excluding the Wall Connector) typically landing between ~$300 and $6,000+, driven by circuit length, routing (wall vs. trench), and available electrical capacity. You’ll choose between clean Garage Installations and rugged Driveway Setups, always permitting and inspecting to NEC 625 and local amendments.

- Same-wall, short run (≤10 ft) from panel; 60A circuit, copper THHN in surface EMT; permit, labeling. Typical: $300–$900.

- Standard garage run (30–60 ft), finished walls; attic/basement fishing, AFCI/GFCI as required, 6 AWG copper/aluminum per ampacity. Typical: $900–$1,800.

- Exterior driveway pedestal: trench 20–60 ft, PVC Sch 40 underground, 18–24 in burial per 300.5, weatherproof box/bollard. Typical: $1,800–$4,500.

- Long run or capacity-constrained: subpanel, load management, or service upgrade; coordination with utility. Typical: $3,000–$6,000+

Incentives, Rebates, and Tax Credits to Lower Your Cost

Those installation ranges can drop materially once you stack incentives. The federal EVSE credit can cover 30% of hardware and installation, up to $1,000, but after 2023 it applies only if your home is in an eligible low‑income or non‑urban census tract—check eligibility rules before claiming. Many states and air districts offer $200–$1,500 rebates, often requiring a permit, final inspection, and UL‑listed equipment. Utility programs may provide make‑ready funds, meter upgrades, or bill credits for enrolling a charger in managed charging; others offer time‑of‑use rates that lower charging costs. To qualify safely, hire a licensed electrician, pull permits, and install per NEC 625/220, including proper conductor sizing, GFCI where required, labeling, and load calculations. Keep itemized invoices and approval emails for audits and verification.

Future‑Proofing and Smart Upgrades to Avoid Rework

While you’re upgrading for a Tesla charger, design for future loads to avoid opening walls twice. Run conduit with spare capacity, upsize wire if code allows, and reserve breaker spaces. Plan networking for software updates and load management. Coordinate permits, arc‑fault and surge protection, and short‑circuit ratings with your electrician to maintain listing, warranty, and inspection approvals. Document photos of concealed runs thoroughly.

Future-proof your Tesla charge upgrade: oversized conduit, reserved capacity, network planning, protections, documented runs.

- Specify a 200A service, or NEC load‑calculated equivalent, to support future EVs and electrification.

- Pull 1‑1/4 in. EMT or PVC to the garage with a spare pull string for modular upgrades and solar/storage.

- Install a 60–100A GFCI breaker and a NEMA 3R lockable disconnect; label circuits per NEC 110.22.

- Choose Wi‑Fi/Ethernet‑ready EVSE that supports OCPP, demand response, and over‑the‑air software updates.

Conclusion

By now, you can test the common theory that “a Tesla home charger always costs thousands.” It doesn’t—when you right-size the circuit, verify load calcs per NEC 220, and leverage rebates, you often land near the low end. You still shouldn’t DIY: hire a licensed electrician, pull permits, and pass inspection. Specify copper conductors, GFCI where required, proper breaker sizing, and load management. Do that, and you’ll charge safely today and avoid costly rework tomorrow.