You want reliable, code‑compliant home charging without surprise costs. Should you use Tesla’s Mobile Connector for low upfront spend, or a hardwired Wall Connector for higher amperage and smart features? The answer hinges on panel capacity, circuit length, conduit, GFCI/AFCI, permits, and utility rates. Get this wrong and you’ll pay more in labor—or electricity—than hardware. Get it right and you’ll qualify for incentives and future‑proof your setup…

Key Takeaways

- Equipment options: Mobile Connector ~$230 (portable, 32A), Wall Connector ~$475 (hardwired, up to 48A), or third‑party Level 2 EVSE $300–$700.

- Installation costs vary by panel capacity, run length, conduit routing, and outdoor needs; electrician labor, permits, and possible panel upgrades often exceed hardware.

- Size circuits as continuous loads at 125%; e.g., 48A charger uses 60A breaker; use copper conductors, required GFCI, and disconnects per code.

- Obtain permits and inspections; keep documentation. Stack federal, state, and utility rebates with pre‑approval to significantly reduce net installation cost.

- Estimate operating cost from kWh at the wall, adding 10–15% losses; enroll in TOU rates and schedule off‑peak charging to save.

Home Charging Options: Mobile Connector Vs Wall Connector

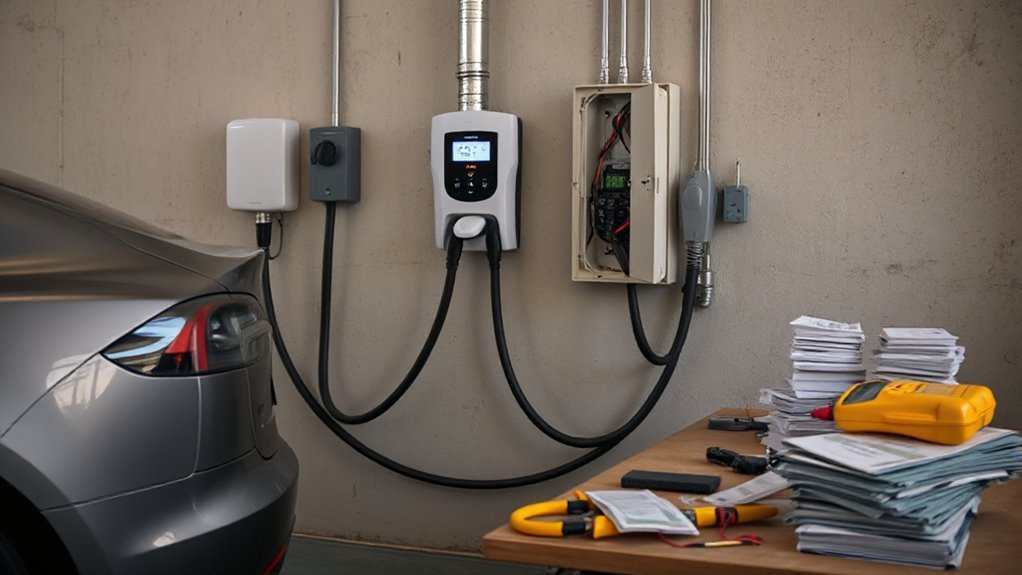

Which option fits your electrical service and daily driving—Tesla’s Mobile Connector or the Wall Connector? If you value Portability Benefits, the Mobile Connector lets you use existing 120V or 240V receptacles with proper NEMA adapters, provided the outlet is on a dedicated, code-compliant circuit with GFCI where required. Verify conductor size, breaker rating, and receptacle condition; don’t exceed the circuit’s continuous load limit. For Aesthetic Integration and a permanent solution, choose a Wall Connector. A licensed electrician should perform a load calculation (NEC 220), install a dedicated breaker, route conduit, set mounting height, and obtain permits. Label the disconnect, torque lugs to spec, and test GFCI. Either way, protect cords from damage and avoid extension cords. Confirm utility capacity and secure required inspection approvals.

Charging Speeds and What They Mean for Daily Driving

How fast your Tesla charges at home depends on circuit voltage, breaker size, your car’s onboard charger, and battery state of charge. For daily driving, replace miles used overnight, not 0–100%. Use a 240 V circuit; continuous loads are limited to 80% of breaker rating.

- Match circuit amperage to the car’s max AC rate.

- Schedule off-peak; precondition while plugged in.

- Set a 70–90% daily limit for battery health.

- Verify conductor gauge, terminations, and GFCI compliance.

Right-sized home speed delivers Range confidence with quiet, predictable mornings and low losses. Faster isn’t inherently better; beyond commute and errand needs, extra amperage adds little. Moderate state-of-charge targets preserve braking headroom, enhancing Regen benefits on departure, while gentler charging reduces heat, voltage drop, and component wear over time.

Hardware Pricing and Feature Comparison

Two common home-charging paths frame the pricing and feature tradeoffs: Tesla’s Wall Connector (~$475) versus the Mobile Connector (~$230) on a properly rated receptacle, with comparable third‑party Level 2 EVSEs typically $300–$700. The Wall Connector delivers up to 48A continuous, integrated Wi‑Fi, power sharing, and a hardwired, weather‑sealed enclosure; the Mobile Connector is portable, 32A max, and relies on the receptacle’s GFCI and rating. You’ll weigh warranty differences, smart features, and build materials against price.

| Aspect | Summary |

|---|---|

| Output/Controls | Wall: up to 48A, app updates; Mobile: 32A, basic |

| Durability | Wall: NEMA 3R, aluminum/polycarbonate; Mobile: compact, corded |

| Compliance | UL‑listed, integral ground‑fault protection; follow NEC continuous‑load sizing |

Networked units can aid load management and utility off-peak compliance. Third‑party EVSEs slot between, offering J1772 flexibility and varied warranties.

Installation Cost Factors: Panel Capacity, Distance, and Site Conditions

Why do installation quotes swing so widely? They hinge on your service panel capacity, the run length to the charger, and site conditions that complicate conduit routing. If your panel lacks amperage or spaces, you’ll need a load calculation and possibly an upgrade, which adds labor and materials. Longer distances require heavier gauge wire, more conduit, and protective hardware, increasing trenching costs for detached garages or driveways. Moisture, corrosion, and seismic considerations also drive hardware choices and mounting methods. A licensed electrician will size conductors, breakers, and GFCI protection to meet code and provide safe, continuous 48A charging.

- Verify service rating, panel spaces, available capacity remaining.

- Measure cable run; minimize voltage drop.

- Plan trench depth, backfill, and marking.

- Choose wet‑location fittings and robust mounts.

Permits, Inspection, and Code Requirements

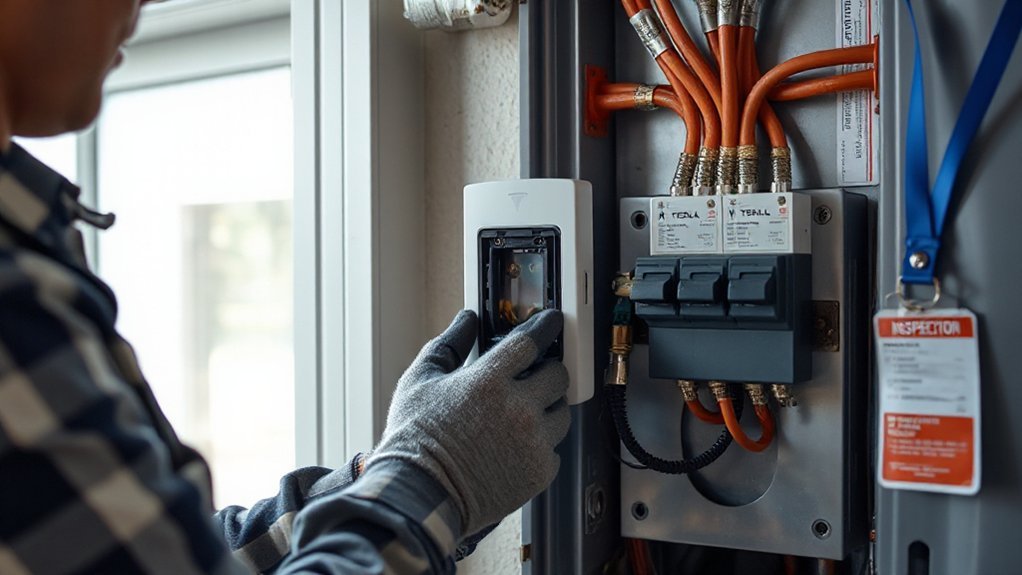

Before you run conduit or order hardware, pull the required electrical permit with your local authority having jurisdiction and plan to pass rough‑in and final inspections.

Confirm permit timelines and submittal method. Provide a load calculation (NEC 220) and identify the circuit as EVSE per NEC 625. Size conductors and the breaker for continuous load: 125% of the Wall Connector’s maximum current (e.g., 60A breaker for 48A output). Use copper conductors and temperature ratings. Maintain working clearances (NEC 110.26), grounding, and GFCI protection where required. Route wiring in conduit, respect fill and bend limits, and seal penetrations. Before inspection, complete an inspection checklist: torque terminations per manufacturer specs (NEC 110.3(B), 110.14), label the branch circuit, verify breaker type, overcurrent sizing, cable support, and height.

Saving Money: Rebates, Tax Credits, and Utility Programs

Planning pays: stack federal credits, state/local rebates, and utility incentives to cut the cost of your Tesla Wall Connector, wiring, and permitting. Verify eligibility before you buy; some programs require pre-approval, licensed electricians, or itemized invoices. Keep permits and inspection sign‑offs; many incentives demand proof of NEC‑compliant installation and conductor sizing. Track Application Deadlines and funding caps—rebates often run out.

Planning pays: stack federal, state, and utility incentives; verify eligibility, keep permits, and watch deadlines.

- Federal credit: claim qualified EVSE and installation on IRS Form 8911 if your location meets current rules.

- State/municipal programs: submit permit numbers, photos, and final inspection; many offer Income based Rebates.

- Utility incentives: rebates for chargers or service upgrades; enroll in approved TOU plans when required.

- Documentation checklist: contractor license, UL listing, load calc, one‑line diagram, and paid receipts.

Submit early to avoid waitlists.

Load Management and Multi-EV Strategies

Although adding a second EV is straightforward, you must manage charging load so your service, feeders, and breakers stay within code and manufacturer limits. Start with NEC Article 220 Load Forecasting to confirm service capacity; treat EVSE as a continuous load at 125% per NEC 625/210.20(A). If the calculation is tight, use Tesla Wall Connector load sharing: network units, set the circuit breaker rating, and let them dynamically apportion current. Configure Priority Scheduling so one vehicle gets full amperage while the other holds or tapers. Limit each EVSE’s max current in firmware to match conductor ampacity and breaker size. Verify feeder voltage drop, temperature rating, and neutral/grounding. Where necessary, add subpanels, upgrade feeders, or sequence charging. Obtain permits, inspections, and label settings for service.

Electricity Rates, Time-of-Use, and Ongoing Operating Costs

Verify your utility’s time-of-use schedule and use the Tesla app to shift charging to off-peak hours, reducing cost and panel loading in a code-compliant way. Estimate charging cost by multiplying the applicable kWh rate (including taxes/fees) by energy added and adding 10–15% for charging losses from the vehicle or wall connector data. If your tariff includes demand or critical-peak pricing, set charge limits and max current to avoid peak periods and prevent breaker trips or conductor overheating.

Peak Vs Off-Peak Rates

When your utility uses time-of-use (TOU) pricing, charging during off-peak hours typically cuts your operating cost per kWh. Program your Tesla or Wall Connector to start after the peak window, align with demand response events, and verify the schedule matches your tariff. Off-peak periods usually have lower grid carbon intensity, so you reduce emissions while easing feeder loading. Maintain code-compliant capacity: confirm your branch circuit, breaker, and service have headroom for the scheduled current.

- Enable Scheduled Charging or Charge Current Limit to fit off-peak amps.

- Use utility rate calendars or API alerts for peak/critical-peak updates.

- Avoid simultaneous large loads; comply with NEC continuous-load sizing (125%).

- If local rules require, add a load management device or EVSE with power sharing.

Document settings for future audits.

Charging Cost Estimation

Because electricity pricing varies by utility and time of day, estimate charging cost from the wall, not the battery display. Use your meter or a smart circuit monitor to track kWh delivered to the EVSE. Multiply kWh by your all-in rate: energy, delivery, taxes, and fixed fees. Apply TOU schedules; schedule charging in off-peak windows. Account for charging losses (typically 10–15%) and preconditioning loads. Check if your utility adds demand charges or tiered rates; these can raise marginal costs. If you add a dedicated 240V circuit, keep it code compliant (NEC sizing, GFCI where required) to protect equipment and avoid insurance implications. Document installations and bills; lower verified operating costs can improve resale value. Reassess rates annually. Include rooftop solar or credits when applicable.

How to Choose and Plan a Future-Proof Setup

How do you choose and plan a Tesla home charging setup that stays safe, code-compliant, and ready for future needs? Start with a load calculation (NEC 220) and panel assessment. Size a dedicated circuit (60A typical for Wall Connector) with copper conductors, GFCI where required, and a listed disconnect if outdoors. Permit job, schedule inspection. Design for Aesthetic integration and clean Cable routing that protects conductors and minimizes trip hazards. Pre-wire conduit for a second EV or higher amperage.

Plan a code-compliant, future-ready Tesla charger: NEC 220 load calc, 60A copper circuit, GFCI/disconnect, permitted install, tidy routing, pre-wire for expansion.

- Choose NEMA 14-50 only when load capacity and location suit; prefer hardwired for durability.

- Place the charger within 2–3 feet of parking to reduce voltage drop and strain.

- Specify surge protection and whole-home AFCI/GFCI compatibility.

- Label breakers, keep clearances, and document settings for future upgrades.

Conclusion

You’ve seen how the Mobile Connector minimizes upfront cost, how Wall Connectors maximize current, and how installation drives the budget. You verify panel capacity, you size conductors correctly, you pull permits. You follow NEC requirements, you protect with GFCI/AFCI, you schedule inspections. You leverage rebates, you program TOU charging, you plan load sharing for future EVs. Choose equipment deliberately, document work thoroughly, hire a licensed electrician, and charge safely, efficiently, and code‑compliantly every day today.